Kích thước và màu sắc

Tỷ trọng: 2.3-2.4g/cm3

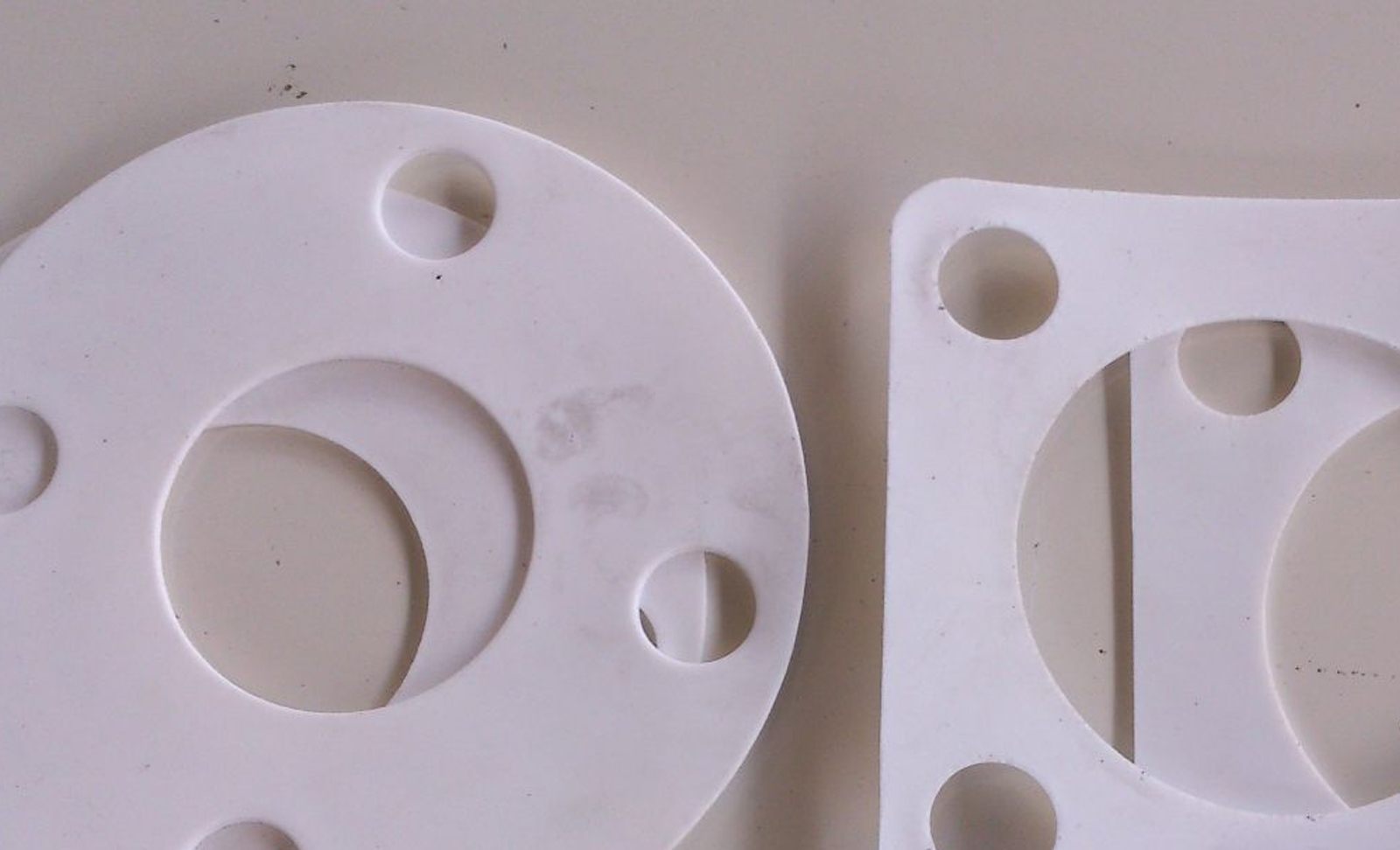

Teflon có rất nhiều loại: Nhựa Teflon tấm, nhựa Teflon cây, nhựa Teflon màu trắng, nhựa Teflon màu đen. Mỗi loại nhựa có một kích thước và màu sắc khác nhau, tiện cho nhu cầu sử dụng của từng loại sản phẩm.

Nhựa Teflon dạng cây: Kích thước 1000mm với số lượng phi đa dạng từ φ6–φ250 mm.

Nhựa Teflon theo màu sắc có màu trắng và màu đen.

Nhựa Teflon dạng tấm: Có đầy đủ các loại kích thước 1000x1000mm, 1000x10000mmvới đa dạng các loại độ dày từ 5mm đến 40mm

Đặc tính cơ lý hóa của nhựa Teflon

Nhựa Teflon có hệ số ma sát cực kỳ thấp, chỉ 0,04, chỉ đứng thứ 2 sau kim cương, tuyệt đối không bám dính với bề mặt của bất cứ loại đồ dùng, vật liệu nào.

Nhựa Teflon không bị giòn đi trong không khí lỏng, không mềm trong nước đun sôi, không biến đổi trạng thái ở nhiệt độ -190 độ C đến 300 độ C.

Nhựa Teflon có khả năng cách điện trên mức lý tưởng, khả năng chịu nhiệt cao lên tới 250 độ C, nhiệt độ làm việc và nhiệt độ nóng chảy cao,…

Nhựa Teflon không có phản ứng với bất cứ hóa chất nào bởi vì chất liệu của nó chịu được hóa chất tốt, chịu được tia cực tím, không thấm nước, không thấm dầu.

Không độc hại, do đó PTFE được sử dụng nhiều trong công nghiệp thực phẩm cũng như dược phẩm.

Ứng dụng của Teflon

Nhựa Teflon được ứng dụng phổ biến trong ngành công nghiệp thực phẩm cũng như dược liệu bởi những tính năng vượt trội và không chứa, không có khả năng gây độc hại cho sức khỏe người sử dụng. Chúng ta có thể nhìn thấy sự có mặt của nhựa Teflon mọi lúc mọi nơi trong cuộc sống này.

Nhựa Teflon xuất hiện nhiều nhất vẫn là ở các sản phẩm để làm lót cho các phễu chứa, hộp chứa, máng trượt và các thiết bị vận chuyển bằng trọng lực nhằm tăng cường khả năng trượt, giảm thiểu khả năng tắc nghẽn.

Ngoài ra nó còn được dùng để chế tạo các chi tiết máy như ổ trượt, bạc lót,… là những chi tiết cần đến độ ma sát thấp, không bám dính và có khả năng chạy rà tốt.

Nhựa Teflon tạo ra một chất polymer có rất nhiều đặc tính tuyệt vời mà các loại chất dẻo khác không thể làm được như: Độ bền cao, khả năng cách nhiệt tốt, không dẫn cháy, hệ số ma sát nhỏ và khả năng chống mài mòn tốt nhất.