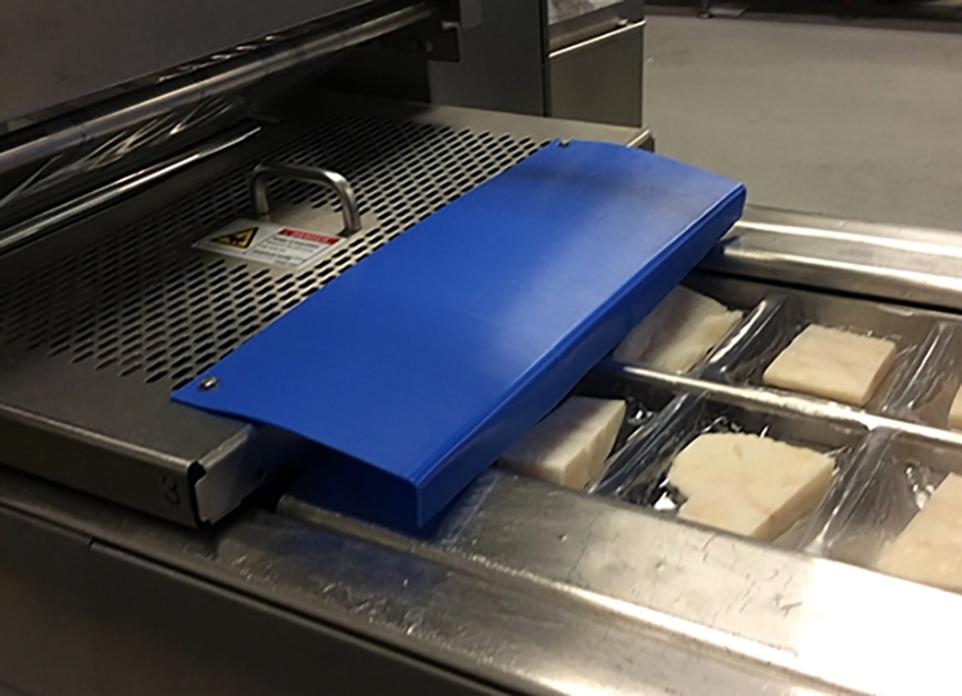

The food industry's most extensive portfolio of certified products

Food processors benefit from the broadest portfolio from PE to PEEK and the most successful know-how in the industry. We are continuously working on the innovation of specialized engineering plastics. Our products feature special developments such as metal detection or antistatic materials and are a continuous process in close cooperation with our customers.

Product safety through good manufacturing practices (GMP)

Product safety for you: All shapes and finished parts from Quadrant plastics for the food industry are manufactured to the most modern manufacturing standards including consistent quality control (GMP).

Compliance Statement

Each delivery comes with an up-to-date Regulatory Compliance Declaration. This statement significantly reduces your in-house testing time and costs. As the #1 manufacturer in the market Quadrant offers a complete test conditions statement.

Raw material selection and application consultation

Customers benefit from Quadrant's international partner network that helps OEMs select the right materials for their applications. Our application advice is based on consideration of each type of food that comes into contact with plastic parts. Advice is based on the temperature and food contact time of the application.

Supports movement calculation

Move and remove solid contact materials from food; Product safety in warehouse: Independent, external testing laboratory INTERTEK has tested the moving value of Quadrant plastic products. These tests were carried out in accordance with regulation (EU) 10/2011. Their results are documented in our Statement of Compliance. Calculating the move value yourself in your personal application becomes very easy with the help of pre-checked values.

Our Food Industry migration tests include testing on each of the OML and SML guidelines: OML = General Movement Limit: measures the inertness of the material; SML = Specific Movement Limit: demonstrates the assessment of toxicity of each substance. However, it is only possible to assist with calculations and provide material recommendations. Final selection of materials used in a particular application is the responsibility of the customer.