1. Máy CNC

Máy tính nối với máy CNC sẽ điều khiểu chúng di chuyển trên tấm nhựa để tạo ra hình dạng mong muốn.

Ưu điểm của máy CNC

1.Tính chất lặp lại tuyệt vời. Một khi máy được lập trình, sản phẩm mà nó tạo ra phải rất nhất quán.

2.Độ chính xác rất tốt.

3. Tính kinh tế và thời gian ngắn hơn so với in 3d với số lượng lớn.

4. Các lựa chọn vật liệu lớn hơn nhiều so với các tùy chọn có sẵn cho in 3D.

5. Gia công có thể tạo ra các bề mặt hoàn thiện khác nhau.

6. Các chi tiết gia công có đặc tính cơ học tốt hơn đáng kể so với các chi tiết in.

Nhược điểm

1. Máy CNC tạo ra giới hạn hình học so với in 3D.

2. Chất thải tạo ra nhiều trong đó có một lượng phoi vật liệu bị loại bỏ.

3. Chi phí lao động tăng.

4. Đối với nhiều chi tiết, gia công kém hiệu quả do thiết lập máy sai dẫn đến tốn chi phí, thời gian, công sức

2. In 3D

Quá trình in 3D là một quá trình trong đó các chất phụ gia được thêm vào các lớp nhựa nóng chảy cho đến khi chi tiết được hoàn thành.

Ứng dụng của công nghệ in 3D

Việc nhận biết các tính chất của ứng dụng là chìa khóa để sản xuất dưới công nghệ in 3D. Tuy nhiên chúng sẽ không được mạnh khi gia công bằng phương pháp đúc khuôn. Các đặc điểm vật lý cần thiết khác cũng có thể bị ảnh hưởng. Tuy nhiên, Công nghệ in 3D cho phép sản xuất các mẫu phức tạp một cách nhanh chóng.

Ưu điểm của công nghệ in 3D

1. Tốc độ: Một thiết kế phức tạp có thể được dựng từ mô hình CAD và được sản xuất nhanh chóng trong một vài giờ. Điều này cho phép xác minh thiết kế trước khi đầu tư vào sản xuất.

2. Chi phí nhân công thấp: Hầu hết các máy in 3D chỉ yêu cầu một nhà điều hành nhấn nút. Các quá trình sau đó hoàn toàn tự động.

3. Hiệu quả: Chi phí đầu tư thấp, sử dụng ít năng lượng hơn so với máy CNC, lượng khí thải carbon thấp.

Nhược điểm: In 3D không thích hợp sản xuất số lượng lớn; Độ bền và các tính chất khác bị giảm; Sức mạnh và các tính khác bị tổn hại; Lựa chọn nguyên liệu thô đầu vào phát triển, nhưng vẫn còn hạn chế; Chi phí nguyên vật liệu cao hơn; Có một giới hạn kích thước trên các chi tiết có thể được in.

Lựa chọn cách tốt nhất để sản xuất các chi tiết nhựa phần lớn bị ảnh hưởng bởi các yêu cầu vật lý của chúng cũng như số lượng cần thiết. Với 1 vài chi tiết có thể được thực hiện với chi phí hiệu quả nhờ in 3D. Một đơn hàng cho hàng trăm bộ phận có lẽ máy CNC là cách giải quyết tốt nhất. Nếu cần sản phẩm có trọng lượng cao hơn, nên xem xét tới việc đúc áp lực. Một khi đã mất thời gian để xây dựng khuôn đúc thì nó có thể sản xuất ra hàng ngàn, hàng trăm ngàn các bộ phận một cách nhanh chóng và chi phí tối ưu.

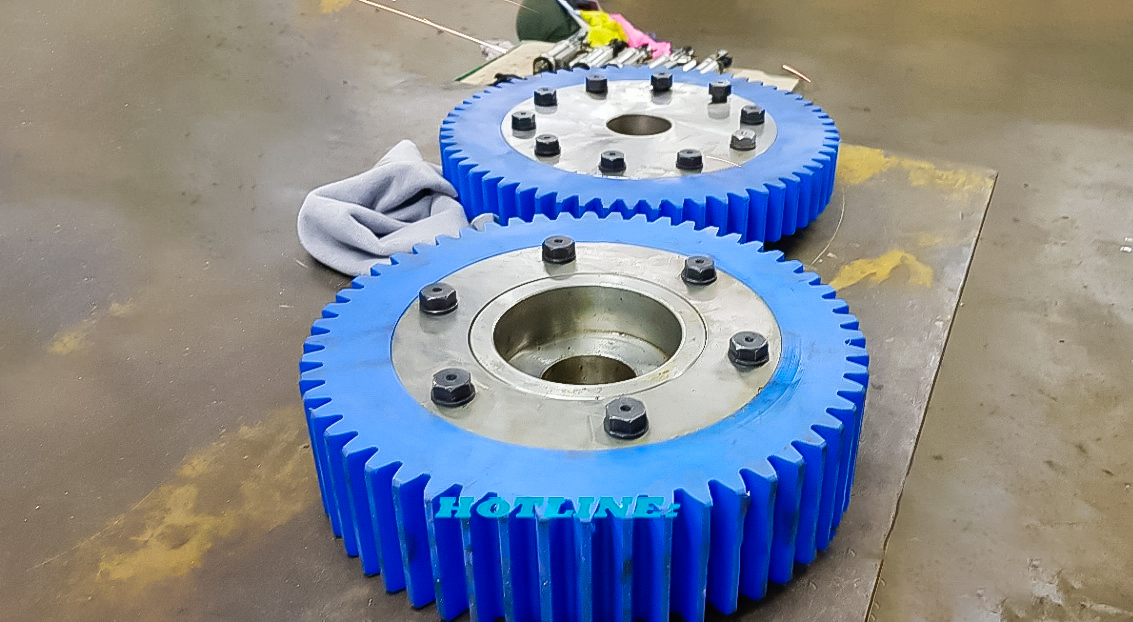

Là công ty đầu ngành trong lĩnh vực cung cấp nhựa nhập khẩu, chúng tôi luôn có các loại nhựa đúc áp lực, đúc đùn. Hệ thống máy CNC được trang bị đầy đủ, có thể gia công chi tiết có độ chính xác và đồng đều. Quý khách hoàn toàn yên tâm về chất lượng các chi tiết nhựa như bulông, bánh răng, đệm bù mòn, píttông, tấm lót xe tải, thanh gạt bùn hoặc nhựa chưa gia công dạng thanh, tấm, cuộn…