Main features

1. Dissipates static electricity permanently

2. Dissipates static electricity [5kV] in less than 2 seconds

3. Do not use metal powder or graphite

4. Depending on base polymer, thermal performance from 90 to 260°C [in continuous use]

Application

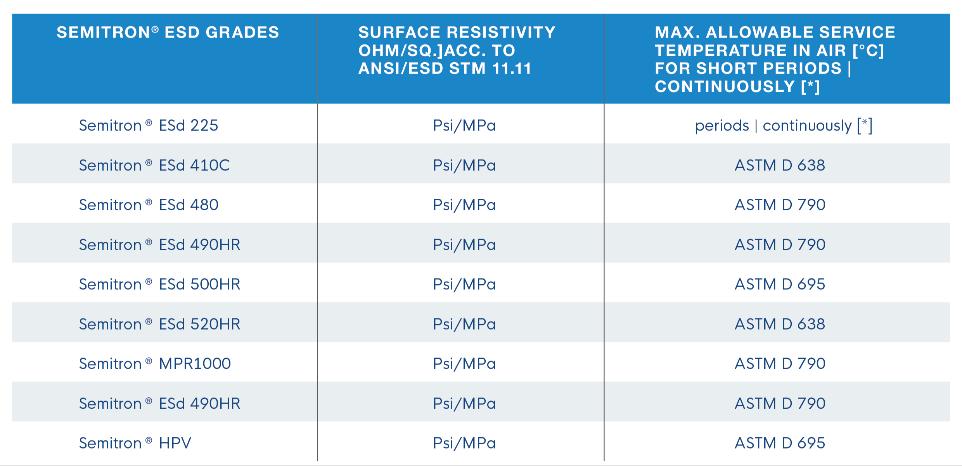

There are eight types of Semitron® ESd that serve dissipation needs over a wide range of temperatures and mechanical load conditions.

Semitron® ESd materials are commonly used in the manufacturing and equipment processing of sensitive electronic components such as integrated circuits, hard drives, and circuit boards. They are also an excellent choice for material handling applications and components in high-speed electronics printing and reproduction equipment.

Chip plugs, direction valves, transport equipment, protective equipment, clean room pads. In addition, anti-static PEI is also used as components and equipment in production lines, auto parts, medical equipment, food, packaging,...

Technology Note: The Semitron® ESd family of resins is inherently self-dissipating and does not rely on atmospheric phenomena [e.g., humidity] for activation nor does it require surface treatments to achieve dispersion.

Main type of plastic

Semitron® ESd 225

[antistatic POM; beige-colored]

Semitron® ESd 225 is an acetal based electrostatic dissipation material for materials handling. It is also a great choice for making jigs for optical drives or handling silicone sheets.

Semitron® ESd 480

[antistatic PEEK; black]

This antistatic PEEK grade provides a dissipation range of 106-109 ohms/sq. Semitron® ESd 480 has high dimensional stability, making it ideal for jig making. Its exceptional chemical resistance makes it well suited for use in sheet processing and other applications such as wet processing tools where electrostatic dispersion is important. Like the Semitron®ESd materials of the MCG line of advanced materials, Semitron®ESd 480 is not subject to dielectric breakdown.

Semitron® ESd 490HR

[antistatic PEEK; black]

This is a slightly higher resistivity Peek material, providing similar physical properties to Semitron® ESd 480. Its surface resistivity is 1010 - 1012 ohm/sq.

Semitron® ESd 500HR

[antistatic PTFE; white]

Reinforced with proprietary synthetic mica, Semitron® ESd 500HR offers the perfect combination of low friction properties, good dimensional stability and electrostatic dissipation. If pure PTFE causes a flashover, Semitron® ESd 500HR provides controlled discharge while maintaining typical PTFE properties such as broad chemical resistance and low coefficient of friction .

Semitron® ESd 520HR

[antistatic PAI; gray khaki color]

Semitron® ESd 520HR Polyamide-imide PAI has a unique electrostatic dissipation pattern to prevent dielectric breakdown at high voltages. Semitron® ESd 520HR PAI is unique in that it maintains its performance over the 100V-1000V voltage range, while providing the mechanical performance needed to excel in demanding applications. This characteristic, combined with high strength and heat resistance makes Semitron® ESd 520HR PAI extremely ideal for test equipment and process equipment applications in electronic semiconductors.

Semitron® MPR1000 [light brown]

Semitron® MPR1000 is a new engineered material developed for semiconductor applications especially vacuum chamber applications such as those found in Etch, CVD and Ion implantation. This material is developed based on three main premises:

1. Longevity - Increased longevity in the plasma chamber compared to traditional plastics such as polyimide (up to 25 times that of polyimide in ozone).

2. Clean – Low metal ion content and little gas emission to the outside.

3. Value - Lower total cost of use compared to traditional materials used in vacuum chamber applications such as quartz, ceramics and engineering plastics.