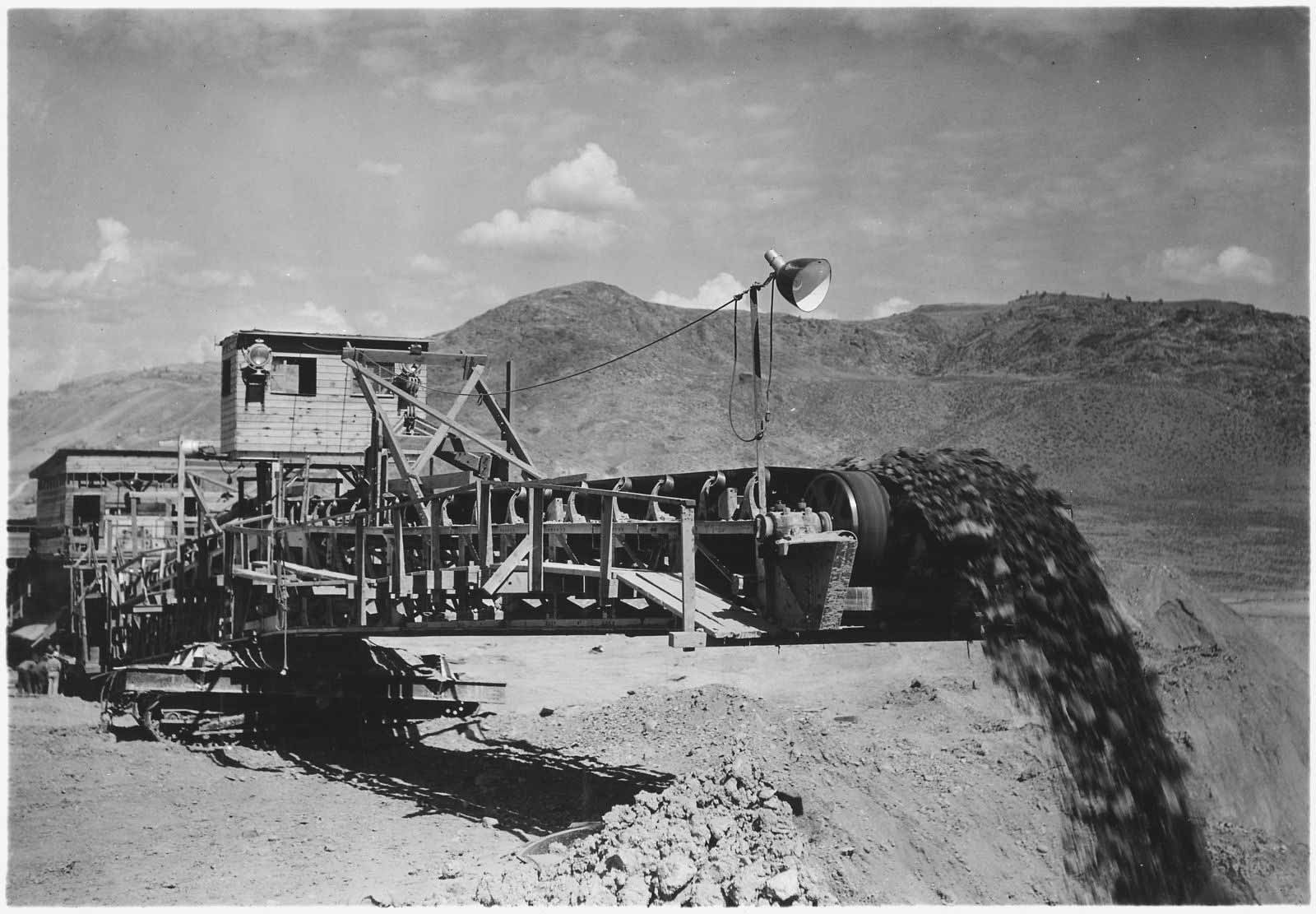

The conveyor system and working were also quite simple in the early days. The conveyor system has a flat wooden bed and a belt that passes over the wooden bed. Previously, conveyor belts were made of leather, fabric or rubber. This primitive conveyor system was very popular for transporting bulky objects from one place to another. At the beginning of the 20th century, the applications of conveyor belts became broader.

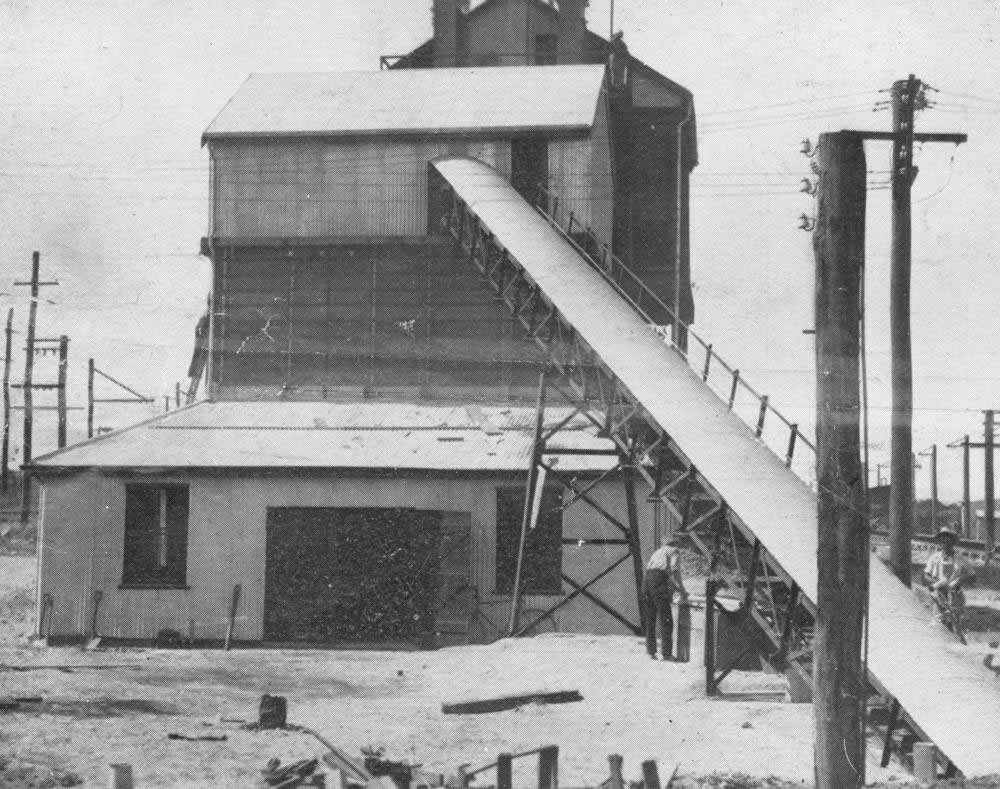

Hymle Goddard was the first to receive a patent for roller conveyors in 1908. The roller conveyor business did not prosper. A few years later, in 1919, supply and free conveyors were used in automobile production. Thus, conveyor belts have become a popular tool for transporting heavy and large goods in factories.

In the 1920s, it was popularized, and also underwent tremendous changes. Conveyors are used in coal mines to handle coal runs for more than 8kms, and have been made using layers of cotton and rubber cover. The longest conveyors currently in use are hundreds of kilometers long, in the Western Sahara phosphate mines.

One of the turning points in its history was the birth of the aggregate conveyor belt. It was introduced during World War II, mainly due to the scarcity of natural materials such as cotton, rubber and fabric. Since then, composite conveyors have become popular in various fields.

With the growing demand in the market, many types of synthetic polymers and fabrics began to be used in the production of conveyor belts. Nowadays, cotton, fabric, EPDM, leather, neoprene, nylon, polyester, polyurethane, urethane, PVC, rubber, silicone and steel are commonly used in conveyor belts.

The conveyor belt industry was introduced to Vietnam in the early years of the twentieth century. Although compared to foreign countries, we have not yet caught up, but we are one of the pioneering companies in the conveyor belt industry and we are proud to be one of the leading companies in the industry. One of the leading conveyor companies in Vietnam. Please contact us so you can keep up with industrial trends in today's developed countries.

Our company specializes in providing conveyor systems (conveyors) such as rubber conveyors, PVC conveyors, roller conveyors, chain conveyors, mesh conveyors, buckets, nets and conveyor belts. Global - Movement for breakthrough"