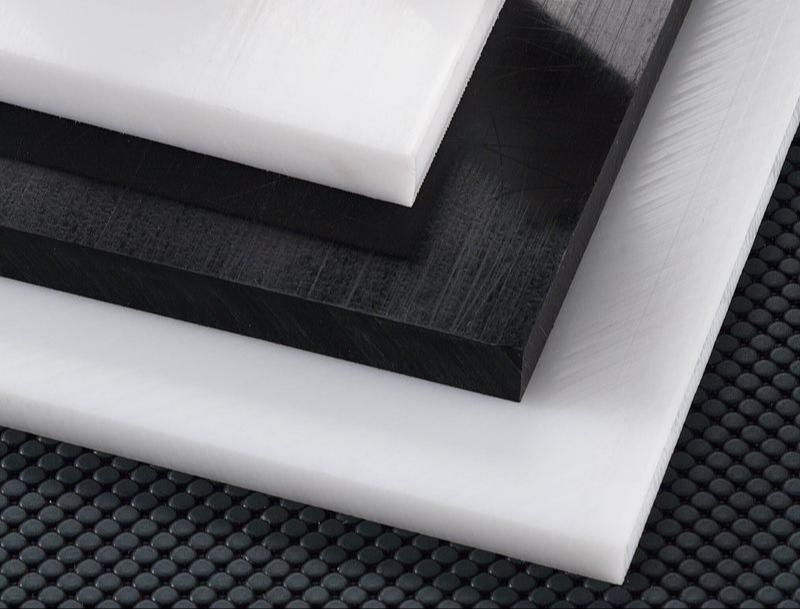

Acetal (polyoxymethylene - POM)

Acetal (polyoxymethylene - POM) là một dạng bán tinh thể nhiệt, định hình nhiệt dẻo. Delrin® (nhãn hiệu DuPont của Acetal), là một homopolymer (Pom H). Nó có cả màu đen và trắng. Một sự khác biệt quan trọng giữa Acetal và nhựa Delrin nguyên bản là Acetal có xu hướng độ rỗng trung tâm. Trong tấm sẽ xuất hiện dưới dạng một dải trắng ở giữa. Cả hai nguyên liệu này đều tuân thủ FDA hoặc 3A (sữa).

POM H

Pom H có điểm nóng chảy là 175 ° C. POM C có nhiệt độ nóng chảy thấp hơn một chút ở 162-173 ° C. Nhìn chung, Acetal có hệ số ma sát rất thấp làm cho nó trở thành một ứng cử viên tốt cho sản xuất vòng bi nhẹ. Như đã nêu ở trên, có hai loại Acetal (POM); một là một copolymer và một là một homopolymer. Mặc dù hai loại có đặc điểm giống nhau và khá tương đồng nhưng có một số khác biệt đáng kể về tính chất của chúng. Acetal copolymer sẽ hoạt động tốt hơn homopolymer trong các lĩnh vực như hiệu suất nhiệt, chịu va đập, mài mòn, kháng hóa chất và nó cũng có tỷ lệ hấp thụ nước thấp hơn. Homopolymer acetal có độ kết tinh cao, do đó tăng cường độ bền cơ học và chống rão. Homopolymer Acetal thường kháng với một loạt các dung môi và các hóa chất thông thường nhưng không hoạt động tốt khi tiếp xúc với các chất oxy hóa và axit mạnh. Copolymer Acetal được sử dụng thường xuyên hơn homopolymer acetal trong các vòi nước, cánh quạt, các bộ phận bơm; trong thời gian ngắn, nơi bao giờ có độ ẩm. Acetal (POM) có độ bền cao, độ cứng và duy trì độ cứng đến -40°C.

Delrin AF (PomH TF)

Delrin AF (PomH TF) là sự kết hợp của 10-25% PTFE, sợi floruacacbon phân tán đồng đều trong nhựa Acetal/Delrin. Các sản phẩm kết quả là một trong đó có sức mạnh, dẻo dai, và ổn định kích thước của Acetal với các tính chất bổ sung của PTFE, đó là một trong những vật liệu trơn rắn nhất thế giới. Trên thực tế, PTFE, thường được gọi là Teflon®, được sử dụng làm vật liệu không dính trên dụng cụ nấu ăn. Khi mài mòn dài và ma sát thấp có trong một ứng dụng, vòng bi làm từ Delrin AF duy trì vận hành cao ở tốc độ cao và ít mài mòn. Các vòng bi không bôi trơn này cũng không bị trượt dính vì các hệ số ma sát tĩnh và động đều bằng nhau. Sự trượt dính là chuyển động giật tự phát có thể xảy ra khi hai bề mặt luân phiên gắn vào và trượt qua nhau với sự thay đổi tương ứng lực ma sát. Vòng bi, bạc đỡ ma sát PTFE không cần bảo dưỡng như các loại bôi trơn khác. Không cần bôi trơn bổ sung. Ngoài ra, PTFE có một trong những nhiệt độ phục vụ cao nhất liên tục trong số nhựa.

Các vật liệu này được sử dụng trong bánh răng nhựa nhỏ trong đồng hồ, đầu vòi phun, cán dao, bộ phận bơm, khóa kéo, vòng bi, bạc đỡ ốc vít và dây buộc trượt tuyết cũng như các dây đàn guitar và nhiều ứng dụng đa dạng khác.