Advantages of plastic gears

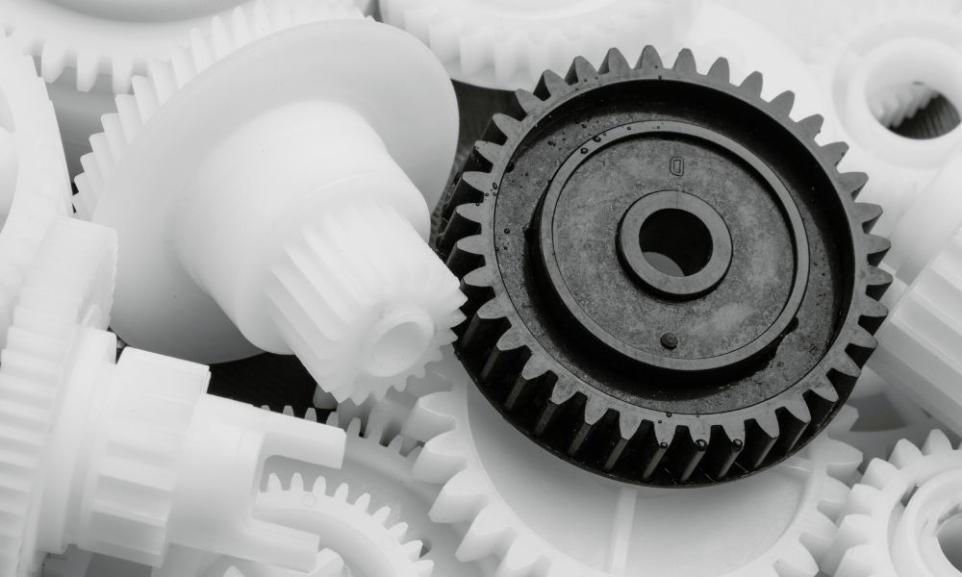

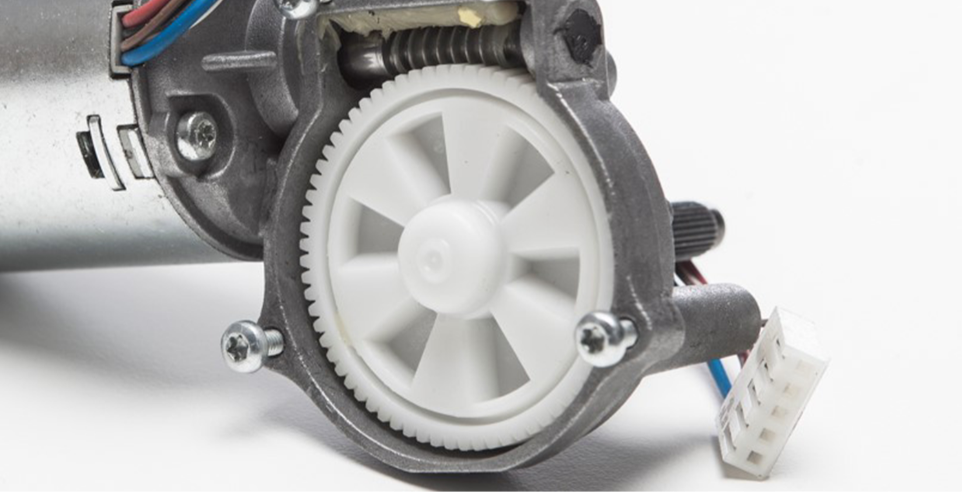

Positive features of plastic gears include being lightweight, stainless, noise-proof, extrusion molding allows low cost and large production, and can operate without lubrication, it can be used in school is clean.

Light and rust-free

One of the biggest advantages of plastic gears is their lightness and rust resistance. Compared to metal gears, plastic gears reduce weight and are not affected by the effects of wet environments. This makes them the ideal choice for applications in industries such as automotive, aerospace and medical.

Noise canceling

Plastic gears also have better noise-canceling properties than metal gears. Plastic has the ability to absorb sound and minimize noise during operation. This makes them popular in applications requiring quiet and high performance such as in industrial machinery and medical equipment.

Low cost and large production

Plastic gear extrusion molding allows large production at low cost. The engineering plastic extrusion molding process helps create gears of precise size and shape without the need for complex machining. This saves time and money during the production process.

No lubrication required

Due to the slippery nature of engineering plastics, plastic gears do not require lubrication for smooth operation. This helps reduce maintenance and save costs.

Operate in a clean environment

Plastic gears can operate in a clean environment without causing pollution. With their stainless properties and corrosion resistance, they are widely used in the medical and food industries.

Note when manufacturing plastic gears

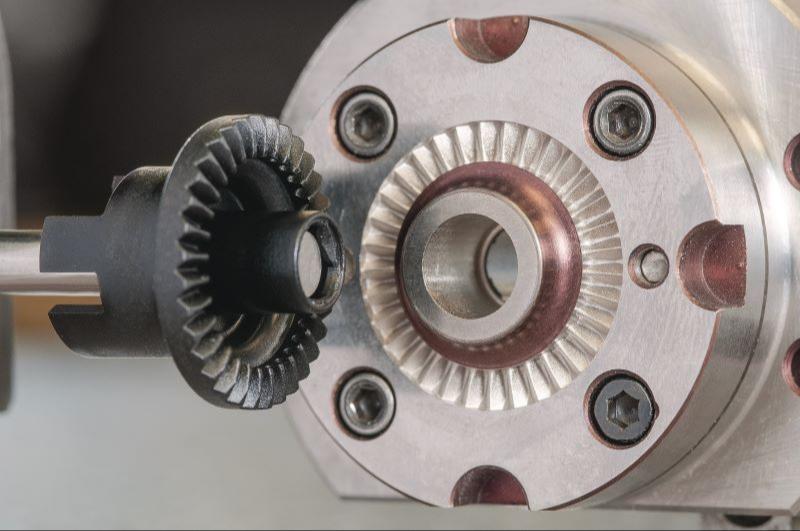

The bending strength of plastic gears is calculated using the Lewis formula. This allows determining the durability of the gear during operation. Decide on material selection based on calculations and requirements of the specific application.

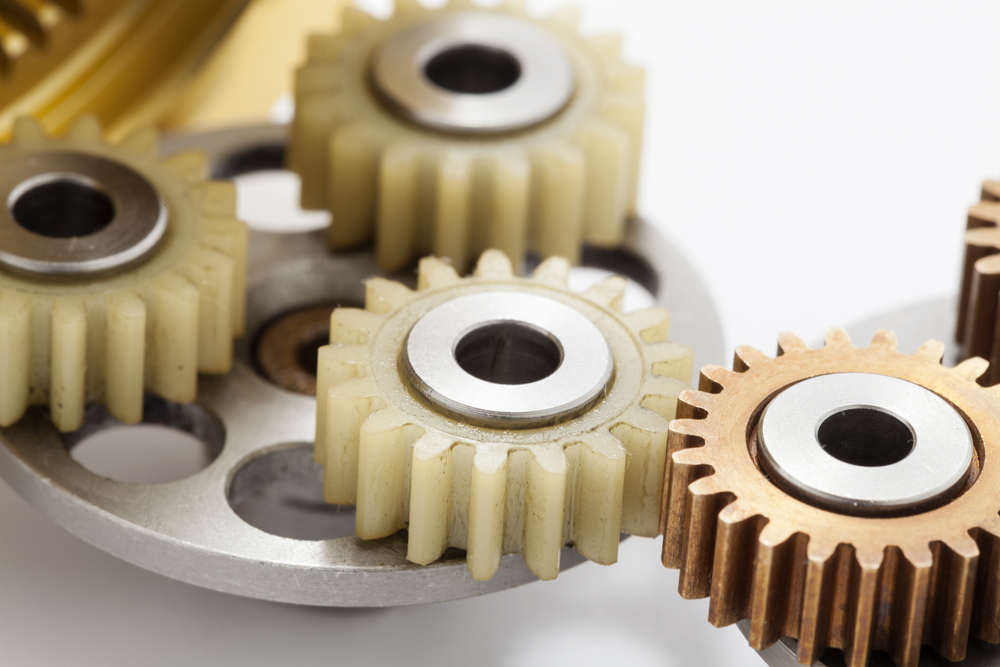

Plastic gears are now commonly used from milky white polyacetal or MC nylon with blue color (polyamide resin). Polyacetal (POM) and MC Nylon are developments of polyamide (PA) plastics. This material is chosen because of its good mechanical properties and good bearing capacity.

In addition, UHMW-PE (ultrahigh molecular weight polyethylene) and PEEK (polyetheretherketone) can also be used in the production of plastic gears. UHMW-PE has high strength and good friction resistance, while PEEK has excellent thermal and mechanical resistance.

Polyacetal (POM) and MC Nylon are two engineering plastics widely used in the production of plastic gears. Both have their own advantages and are chosen depending on the application requirements.

Polyacetal (POM) has high hardness and precision, allowing the creation of highly precise and resistant gears. It also has good friction resistance and high temperature resistance.

MC Nylon has better strength and impact resistance than POM. It also has good friction resistance and high temperature resistance.

Conclude

Plastic gears are becoming a trend in today's industries. The advent of engineering plastics has brought many positive changes to the production and improvement of plastic gears. Features such as lightness, stainless steel, noise resistance, low cost and ability to operate in clean environments have made plastic gears the top choice for a variety of applications. The choice of materials such as POM, MC Nylon, UHMW-PE and PEEK also plays an important role in ensuring the mechanical properties and bearing capacity of the gear. With these outstanding advantages, it is no surprise that plastic gears are becoming a growing trend in today's industries.

Chia sẻ