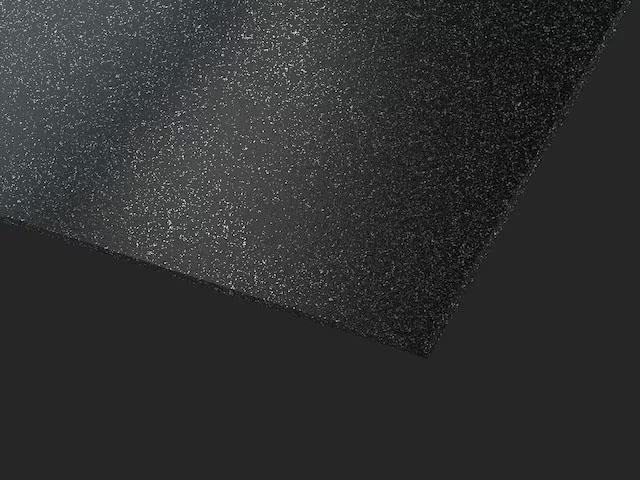

ADVANCED LINING MATERIALS FOR ANY APPLICATION

Because of the amount of movement across shared surfaces, a lining material needs to minimize friction and resist damage. From parcel distribution to bulk raw materials handling, our custom lining offering helps enable and improve mass flow. Our advanced polymers are self-lubricating and abrasion resistant, improving performance and reducing blockages and downtime.

TIVAR® Arctic UHMW-PE →

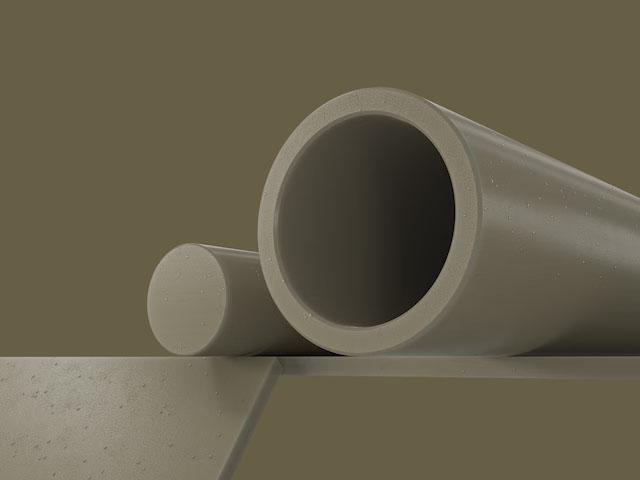

Ultra High Molecular Weight Polyethylene

A lining material with great release properties even in temperatures below -15°C. The material was formulated with active fillers specifically for use in the coldest regions on earth, where subzero temperatures may cause bulk materials to freeze to unlined surfaces.

TIVAR® BurnGuard UHMW-PE →

Ultra High Molecular Weight Polyethylene

A static dissipative and flame retardant material specifically developed to improve the flammability behavior of unfilled polyethylene grades, especially in linings. This grade possesses a UL94 V-0 Flammability Rating.

TIVAR® DrySlide UHMW-PE →

Ultra High Molecular Weight Polyethylene

With an internal lubricant built into the polymer matrix with higher molecular weight, this premium UHMW-PE offers a lower coefficient of friction and enhanced wear and abrasion resistance vs. TIVAR® 1000 UHMW-PE.

TIVAR® Sterra™ DrySlide UHMW-PE →

Recycled Ultra High Molecular Weight Polyethylene

An internally lubricated, recycled lining material that offers a lower coefficient of friction and enhanced wear and abrasion resistance compared with standard UHMW- PE grades.

TIVAR® 88 UHMW-PE →

TIVAR® 88 UHMW-PE is a premium glass- filled grade that offers low moisture absorption, a low coefficient of friction, and excellent chemical resistance. It is recognized worldwide as the premium lining material for bulk material handling.

TIVAR® 88 ESD UHMW-PE →

Ultra High Molecular Weight Polyethylene

Electro-static dissipative lining material that prevents the build up of electrical charges in dusty or volatile environments. This glass- filled grade is commonly used to line storage and transport containers, hoppers, chutes, tubes, bunkers, conveyors, vibratory pans, and stand pipes.

TIVAR® 88-2 UHMW-PE →

Ultra High Molecular Weight Polyethylene

UV-stabilized UHMW-PE lining materials exhibiting a low coefficient, self-lubrication properties, low moisture absorption, excellent chemical resistance. Components can be fabricated and welded for any application that requires a seamless drop-in liner, a framed-in liner, or a replacement liner.

TIVAR® 88-2 ESD UHMW-PE →

Ultra High Molecular Weight Polyethylene

Electro static dissipative lining material that prevents the build-up of electrical charges in dusty or volatile environments. Components can be fabricated and welded for any application that requires a seamless drop-in liner, a framed-in liner, or a replacement liner.

TIVAR® Sterra™ ESD UHMW-PE →

Recycled Ultra High Molecular Weight Polyethylene

An electrostatic dissipative polyethylene that contains recycled UHMW-PE content. A favored lining material for conveyor, chute, and hopper applications, where electrical charge build-ups are prevalent.

CONVEYING & HANDLING SYSTEMS

Liners for distribution warehouse chutes

The solution: A self-lubricating polymer lining with a low coefficient of friction that promotes bulk flow and allows the individual items to slide effectively.

The results: Our impact-resistant TIVAR® DrySlide UHMW-PE lining resolves all blockage issues – including the need for an attendant to monitor operations. The new lining enables the conveyor system to operate fully automatically and eliminates the need to apply costly sprays or waxes.

PRODUCT: TIVAR® DrySlide UHMW-PE

INDUSTRY: Logistics Industry

APPLICATION: Automated distribution chutes

SELF-LOADING & UNLOADING TRANSLOADER

Turnkey installation of flow liners for cargo holdsThe solution: TIVAR® MarineGrade UHMW-PE lining system, 70% pre-engineered and prefabricated kits, and 30% full sheets for onsite installation with supervision.

The results: The turnkey installation of a custom-engineered lining system was the result of seamless global project management across three continents, involving engineering and design, manufacturing and fabrication, and local installation supervision. The 21,500 DWT vessel is operational in Vietnamese waters, serving a local thermal power plant where it transloads coal from a bulk carrier to the onshore coal terminal.

INDUSTRY: Maritime

APPLICATION: Ship cargo holds

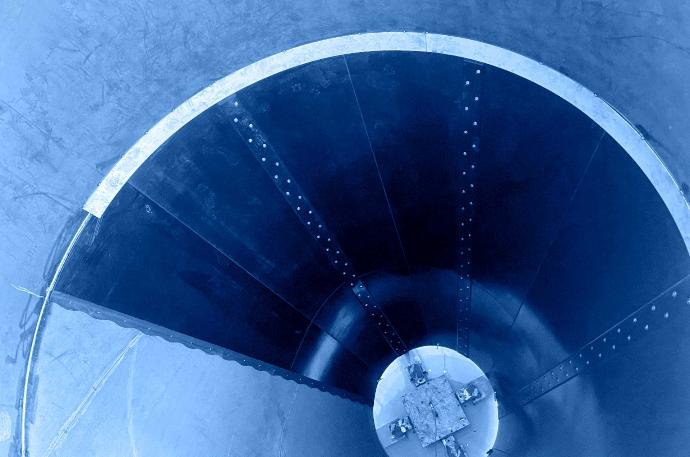

POWER GENERATION & TRANSPORTATION EQUIPMENT

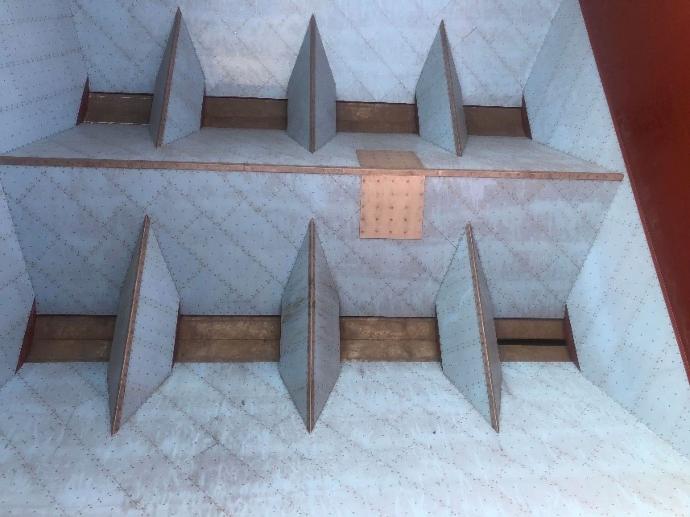

Powerplant coal silo liner & installationThe challenge: To permit lignite coal to discharge in a mass flow pattern, both the design of the coal silos as well as the lining material are taken into consideration. While geometry had been determined, traditional stainless-steel linings were not allowing sticky lignite coal to flow as required.

The solution: A low-friction advanced polymer lining that outperforms steel and enables improved mass flow.

The results: Our TIVAR® 88-2 UHMW-PE improves the release of lignite coal, maximizing flow while also allowing for shallower hopper walls due to a lower coefficient of friction. Fully engineered and prefabricated lining kits were installed with onsite installation supervision in a total of 6 hoppers.

PRODUCT: TIVAR® 88-2 UHMW-PE

INDUSTRY: Energy generation

APPLICATION: Coal silo liner

DROP-IN LINER

Seamless liner installation for chemical transfer hopperThe solution: A polymer lining material with excellent release properties, service temperature up to 110°C. and a drop-in design without any metallic components

The results: The TIVAR® H.O.T. UHMW-PE lining fulfilled the temperature requirements, promoted flow, and eliminated contamination risks. Furthermore, the fully engineered, prefabricated one-piece drop-in design made for an extremely low-effort installation, thereby avoiding the cost of a conventional, piece-by-piece installation.

PRODUCT: TIVAR® H.O.T. UHMW-PE

INDUSTRY: Chemical Processing

APPLICATION: Transfer hopper liner

Premium Truck Liner QuickSilver® UHMW-PE →

Ultra High Molecular Weight Polyethylene

Polyethylene bed liners that protect the integrity of original truck beds and improve the release of viscous materials for quicker unloading, greater safety, and less carryback.

Material properties at a glance

• Extends wear life of truck bed

• Superior impact strength and abrasion

resistance

• Improved unloading of viscous materials

Premium Truck Liner QuickSilver® HD UHMW-PE →

Ultra High Molecular Weight Polyethylene

Heavy duty bed liners that protect the integrity of original truck beds and improve the release of materials for quicker unloading, greater safety, and less carryback.

Material properties at a glance

• Extends wear life of truck bed

• Superior impact strength and abrasion resistance

• Improved unloading reduces need for costly flow agents

DUMP TRUCK BED LINERS

Semi-trailer truck liningThe challenge: A semi-trailer was hauling typical construction materials with frequent tip-outs per day. Though the trailer was equipped with wear-resistant steel plates to protect the aluminum bed from abrasion, the downside was carry-back when hauling sticky materials. This lead to a reduced payload due to additional weight.

The solution: A lightweight plastic lining material with improved wear resistance that eliminates carry-back, saves cleaning time and weighs less than steel wear plates.

The results: Our QuickSilver® HD UHMW-PE liner eliminates carry-back and has a longer service life than a standard polymer lining material, competing with that of the previous steel liner. The benefit of the time savings and additional payload due to weight made the plastic liner advantageous over previously installed steel liners.

PRODUCT: QuickSilver® HD UHMW-PE

INDUSTRY: Construction

APPLICATION: Dump truck bed liner