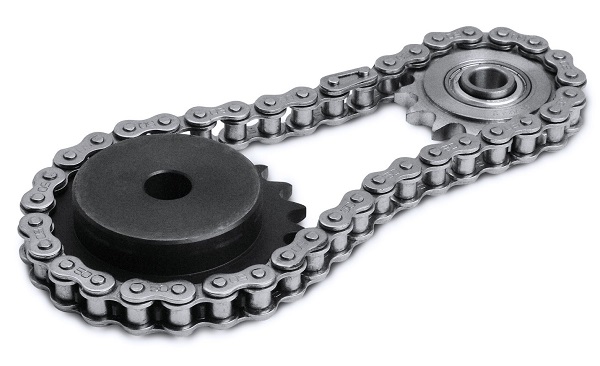

Function of roller chain

Roller chains have the advantage of a simple and easy mechanical energy transmission technique. Roller chains are constructed like a standard chain link system, with several cylindrical rollers connected by links. The chain is moved by a rotating sprocket attached to the motor. The opposite end of the chain can then be attached to a weight.

The roller is susceptible to shock loading when it impacts the sprocket teeth. The contact point and its balance change after engaging each other. It is held between the sprocket teeth and the bushing and moves on the tooth face when subjected to compression.

In addition, when the roller rotates on the rail, the inner surface of the roller, together with the outer surface of the bushing, forms a load-bearing part. Therefore, it must be resistant to wear while also resisting shock, fatigue and strong compression.

Purpose of roller chain

To transport materials or goods from one location to another.

• To ensure that an action is performed consistently after the previous step.

To change the direction of motion from linear to rotary.

. To disperse power

Roller chains offer significant benefits over belt drives for these operations because they have minimal slip or pull on the chain even under heavy loads, and are extremely efficient and long-lasting . Roller chains have outstanding durability and longevity thanks to excellent heat treatment and a 100% lubrication process.

Uses of roller chains

1) Drive chain rollers are usually smaller in diameter than the height of the chain's link plates. Therefore, when the chain meshes with the sprockets, the link plates act as guides, and they can also act as guides while the chain runs in principle, as in a bucket elevator.

2) Conveyor chain rollers are often much larger in diameter than the width of their side bars. It is done for two reasons:

• Large rollers, called carrier rollers, carry the side bars above the conveyor line, avoiding friction; And

• Larger rollers have a distinct mechanical advantage over smaller rollers in terms of rotational friction, which reduces chain pull.

3) Most chains use carrier rollers to engage the sprockets. On the other hand, bearing rollers with anti-friction bearings are sometimes used as outboard rollers on chains without rollers. Rollerless chains are similar to roller chains and are used in situations where rollers are not required.

There are many different types of roller chains and all are made for a specific application. All roller chains are made with rollers spaced evenly along the chain. The fact that the rollers rotate when they contact the sprocket teeth is a significant benefit of roller chains.

Types of roller chains

Roller chains are used for both driving and transport purposes. Each application area has its own type of chain. Standard transmission roller chains are classified into three types:

• Single chain (40 chain, 50 chain, 60 chain, 80 chain, 100 chain, 120 chain, 140 chain, 160 chain, 180 chain, 200 chain, 240 chain)

• Multi-row chains, and

• Double step chain

Standard single row roller chains are commonly used for transmissions. The power rating of these chains meets a wide range of drive load needs. Multi-cord roller chains increase capacity without increasing chain pitch or linear speed. A multi-row chain with a lower rake angle can run faster than a single-row roller chain with a larger pitch for a given capacity load. Double pitch chains are ideal for drives with slow speeds, moderate loads or long center distances.