Khám phá về băng tải xích nhựa

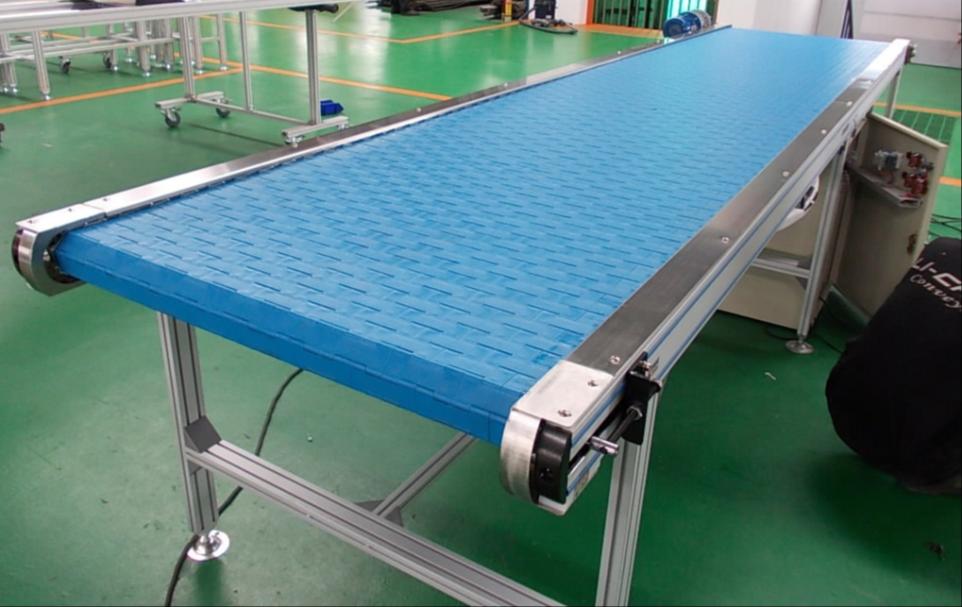

Băng tải xích nhựa là một dạng phổ biến của băng tải, được sử dụng trong nhiều ngành công nghiệp. Băng tải này được làm bằng nhựa, vật liệu mà có thể chịu được những tác động môi trường nặng nhẹ, với độ bền cao. Băng tải xích nhựa có thể được sử dụng trong các hệ thống đường băng tải, để di chuyển các vật liệu trong các ngành sản xuất, kinh doanh, công nghiệp và giao thông. Băng tải xích nhựa có thể được sử dụng trong các ứng dụng như để di chuyển dầu, than, đồ đạc, gỗ, thực phẩm và các sản phẩm khác. Nó có thể di chuyển trong các hệ thống băng tải nhỏ, và có thể được sử dụng trong các hệ thống băng tải lớn. Băng tải xích nhựa có thể được sử dụng trong các hệ thống băng tải tăng tốc hoặc các hệ thống băng tải dự phòng. Băng tải xích nhựa có thể được sử dụng trong các hệ thống băng tải cố định hoặc di động. Băng tải này có thể được lắp đặt trên các tầng, để tạo ra một hệ thống băng tải cố định. Băng tải xích nhựa cũng có thể được sử dụng trong các hệ thống băng tải di động, với các đế xe di chuyển trên đường băng tải. Băng tải xích nhựa có nhiều ưu điểm, bao gồm các đặc điểm như độ bền cao, trọng lượng nhẹ, ít bị hư hỏng, khả năng di chuyển dễ dàng và chi phí thấp. Băng tải xích nhựa cũng có thể được sử dụng trong các hệ thống băng tải dự phòng, và có thể được sử dụng trong các ứng dụng cố định hoặc di động.

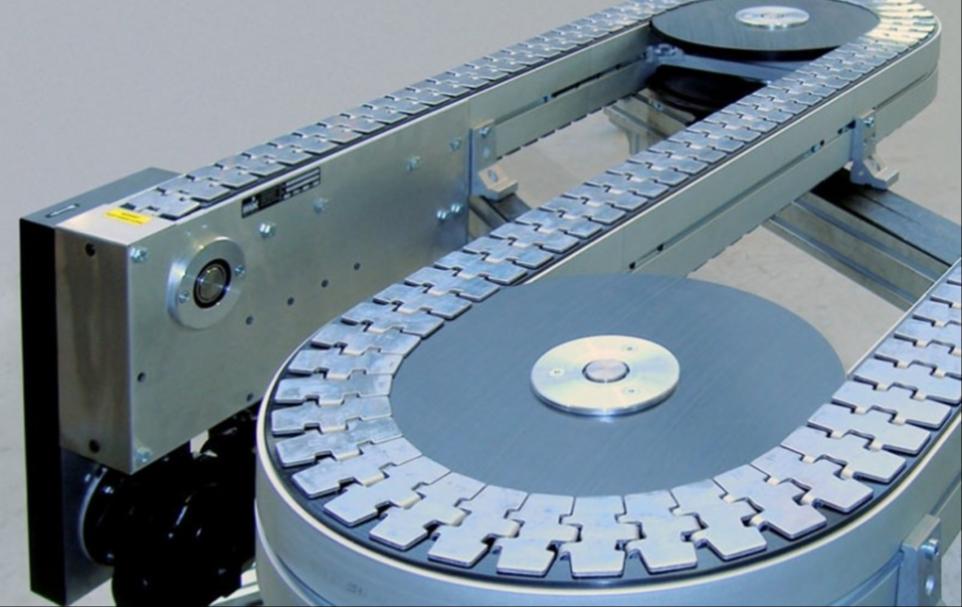

Tổng quan về cấu trúc của băng tải xích nhựa

Băng tải xích nhựa là một loại băng tải phổ biến được sử dụng trong nhiều lĩnh vực khác nhau, bao gồm cả các ngành công nghiệp như dầu khí, gỗ và nông nghiệp. Băng tải xích nhựa được làm từ vật liệu cao su hoặc nhựa, có thể được sử dụng trong rất nhiều môi trường và có thể chịu được các tải trọng lớn. Băng tải xích nhựa được tạo thành từ một vòng xích mềm có thể là nhựa hoặc cao su, cùng với một lớp nhựa hoặc cao su bọc quanh nó. Xích được gắn với một hoặc nhiều đường cong trên lớp bọc, được đặt cạnh nhau và được gắn với nhau bởi một dây kéo hoặc một loại vật liệu khác. Băng tải xích nhựa có thể được sử dụng để vận chuyển hàng hóa, hàng hóa dễ vỡ hoặc hàng hóa nặng. Băng tải xích nhựa có nhiều ưu điểm so với các loại băng tải khác. Nó có thể chịu được tải trọng lớn hơn và có thể được sử dụng trong môi trường cực tốc. Nó cũng có thể được sử dụng trong môi trường đông đúc và không bị hư hỏng vì không khí. Vì vậy, băng tải xích nhựa là một sự lựa chọn hiệu quả và bền vững cho các doanh nghiệp vận chuyển hàng hóa.

Khả năng ứng dụng của băng tải xích nhựa trong hệ thống sản xuất

Băng tải xích nhựa là một trong những phần quan trọng của hệ thống sản xuất. Nó được sử dụng để di chuyển các loại hàng hóa trong các nhà máy và các công trình sản xuất, đặc biệt là những công trình có nhiều buôn bán. Những băng tải này có thể điều khiển tốc độ và hướng di chuyển của hàng hóa và sản phẩm của bạn, giúp bạn thuận tiện và giảm thời gian sản xuất. Băng tải xích nhựa cũng có thể giúp bạn giảm được sự rối mắt và áp lực khi thực hiện một quy trình sản xuất. Nó cũng giúp bạn tăng hiệu suất và giảm thời gian sản xuất. Băng tải xích nhựa cũng có thể giúp bạn giảm thải động và giảm mức độ ô nhiễm môi trường. Băng tải xích nhựa có nhiều loại khác nhau, nhưng những loại thông dụng nhất là băng tải xích nhựa lớn, băng tải xích nhựa nhỏ, băng tải xích nhựa cao su, băng tải xích nhựa đứng và băng tải xích nhựa trượt. Ngoài ra, những băng tải xích nhựa cũng có thể được trang bị các thiết bị điều khiển và điều chỉnh để cải thiện hiệu suất và tiết kiệm điện năng. Tổng kết, băng tải xích nhựa là một trong những thành phần quan trọng của hệ thống sản xuất. Nó có nhiều lợi ích cho sản xuất, bao gồm giảm thời gian và công sức, tăng hiệu suất, giảm thải động và giảm ô nhiễm môi trường. Ngoài ra, các băng tải xích nhựa cũng có thể được trang bị các thiết bị điều khiển và điều chỉnh để cải thiện hiệu suất và tiết kiệm điện năng.