Plastic conveyor chains not only set the industry standard for quality and innovation, but also provide solutions applicable to a wide range of products and industries.

To choose a conveying solution for your project, there are many types of conveyors to choose from. Belt conveyors and roller conveyors are the most commonly used. However, the high-strength, chain-shaped design is the solution for many types of products and industries. They offer the most design flexibility and the lowest total cost of ownership compared to all other conveyor types.

Plastic chain conveyor systems are used by many industrial production industries. With many superior features, conveyor belts

Plastic chains are extremely popular in the food and beverage processing industry. In this article, we will learn about the characteristics of plastic conveyor chains that make them more suitable for these industries than other types of conveyor belts.

What is plastic conveyor chain?

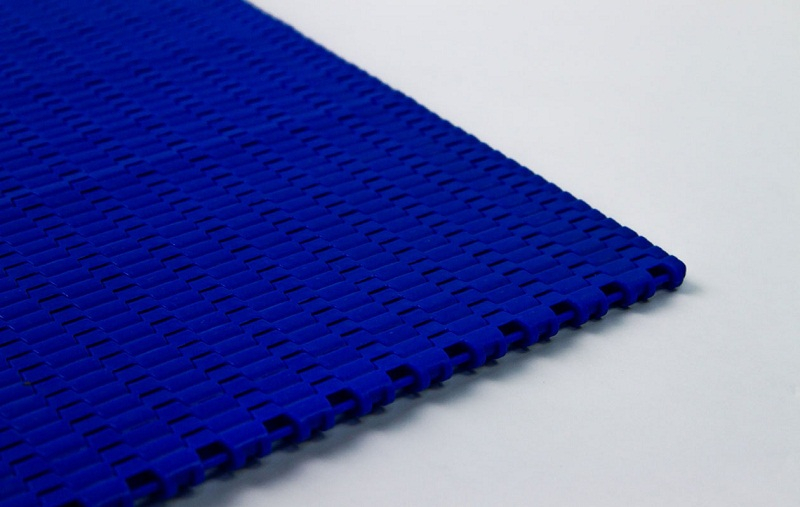

Plastic conveyor chain is a part of the conveyor system made from high quality plastic. Plastic conveyor chains are commonly used to transport products, goods and materials during production, processing and transportation in various industries.

Plastic conveyor chains are widely used in the food, beverage, packaging, textile and garment industries, and many other industries with requirements for gentle transportation, no harm to products and durability in the environment. hard.

Benefits of using plastic conveyor chains

Below are some of the benefits of using plastic conveyor chains for industries.

1. Easy to clean and maintain

The structure of the plastic conveyor chain is made to suit hygienic conditions so it is easy to clean. Plastic belts are also hygienic and can be cleaned easily. These characteristics are highly valued in the food and beverage and pharmaceutical industries because even a small amount of contamination can cause an entire batch of product to be recalled.

2. Reduce the risk of product damage

The top of the plastic chain is smooth for easy moving of the product. Plastic conveyor chains are gentler on your products or packages, thus reducing the risk of damage. Product and packaging damage is a major factor in the consumer products industry and therefore maximum quality must be ensured through the use of appropriate shipping solutions.

3. Better belt tracking

Plastic chain conveyors operate using sprockets instead of pulleys. Sprockets allow for better, more streamlined belt flow, reducing the likelihood of large track failures. Furthermore, overall stability keeps products stable on the conveyor belt, maintaining their position and eliminating the need to frequently check products.

4. Flexibility of layout

The layout configuration and flexibility of plastic chain conveyors make it easy to rearrange the production line. Many businesses, especially in the food packaging industry, regularly rotate their packaging solutions, and so the versatility that plastic chain conveyors offer makes it a perfect choice. Furthermore, these conveyors are light and easy to move, making installation and relocation simple.

Types of plastic chains are commonly used today

Modular rebuildable chain components mean easy repairs on your line. Durable chain designs, not only set the industry standard for quality and innovation, but also provide application solutions for a wide variety of products. Below are the top 5 types of plastic conveyor chains commonly used today:

1 - The plastic conveyor chain is super tight

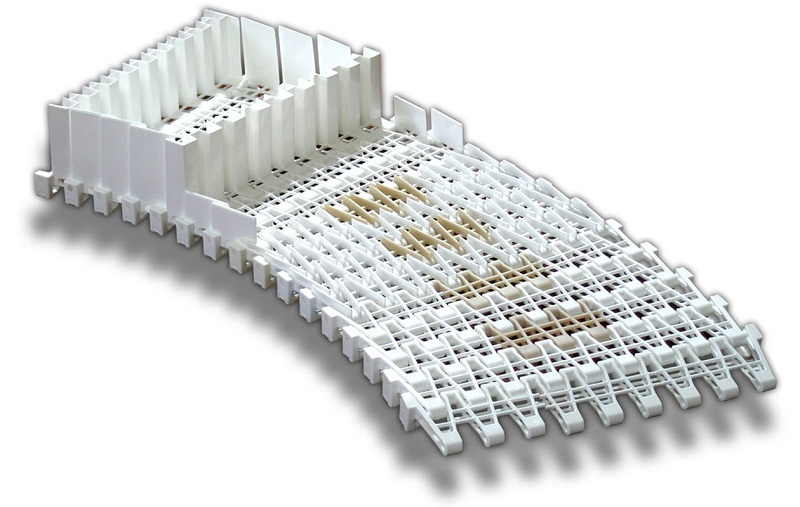

A long chain pitch means it uses half as many links to accomplish the same job. This chain has the smallest turning radius on the market today. Super quality plastic conveyor chains are the perfect solution for applications requiring high performance, low cost conveyors. Because the pitch of this chain is twice that of other chains, conveyors of the same length use half the number of chain rows. Its open design allows good airflow to your products, perfect for cooling or drying applications.

This type of plastic conveyor chain is commonly used in food production or packaging applications. Plastic chain conveyors help transport goods effectively, optimizing the transportation process.

2 - Sealed plastic conveyor chain

The sealed top has an internal roller resulting in extremely low running friction. This means you have the option of creating extremely long conveyors of 100m or more. Enclosed conveyors only run straight but can carry heavier products due to additional internal bracing structures.

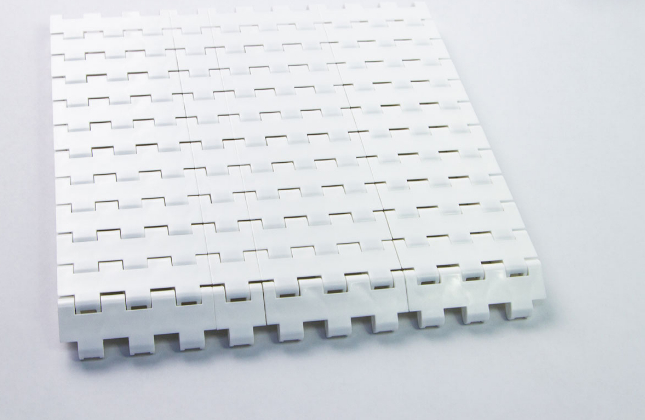

3 - Modular plastic conveyor chain

Modular chains can be implemented easily and quickly without the hassle and expense of replacing or repairing belts on conveyors. Modular plastic chain conveyors can be implemented with modular chains to handle practically any product.

• 4 mm flat, smooth surface

High friction, used on inclined surfaces where the product surface is soft and the points can assist in gripping the product

• 6mm flat: Used in applications requiring stronger chains

High friction increased to 6 mm: Used in applications requiring stronger chains

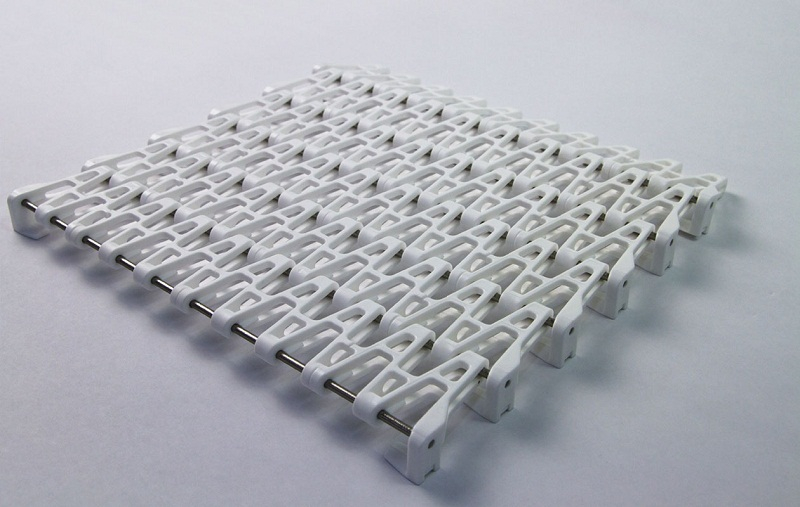

4 - Flexible plastic conveyor chain

Plastic chain has a flexible design and is the top choice for its product cooling ability. Innovative conveyor chains are adaptable in design and can cost you less. Using a 75% open design, liquids and debris can fall through the line, meaning there will be less downtime due to belt cleaning. The open design also saves costs due to reduced material usage.

Additionally, the modular design allows each individual section of the line to be opened, so servicing and maintenance is easy.

The all-plastic design also makes it a great choice for running through metal detectors.