1. Nhựa PEEK là gì?

Nhựa PEEK Là Gì? Đây là câu hỏi không ít khách hàng vẫn còn rất mơ hồ về khái niệm và tính năng vượt trội của dòng nhiên liệu này. Nhựa PEEK được sản xuất thông qua quy trình đúc các loại nhựa polyetheretherketone ở nhiệt độ phù hợp.

Poly Erherethe Ketron chính là tên gọi khoa học của nhựa PEEK. Vật liệu được phát hiện từ đâu năm 1978 bởi Tập đoàn ICI ở Vương Quốc Anh. Cấu trúc hóa học chính của Nhựa PEEK được hình thành từ nhiều vòng Benzen nối tiếp nhau thông qua 2 nhóm: nhóm ether (-O-) và ketone (-C(=O)-).

Thông thường, kích thước của nhựa PEEK sẽ phân chia thành 2 loại, cụ thể như sau:

* Nhựa PEEK ở dạng tấm: 600x1000mm là kích thước phổ biến nhất với độ dày giao động từ 5mm đến 60mm.

* Nhựa PEEK ở dạng cây: Đường kính trung bình từ φ5 đến φ200mm với kích thước tiêu chuẩn là 1000mm.

* Ngoài ra, nhựa PEEK cũng được sản xuất với đa dạng màu sắc như nâu đậm, đen, trắng hoặc xám để đáp ứng nhu cầu của thị trường.

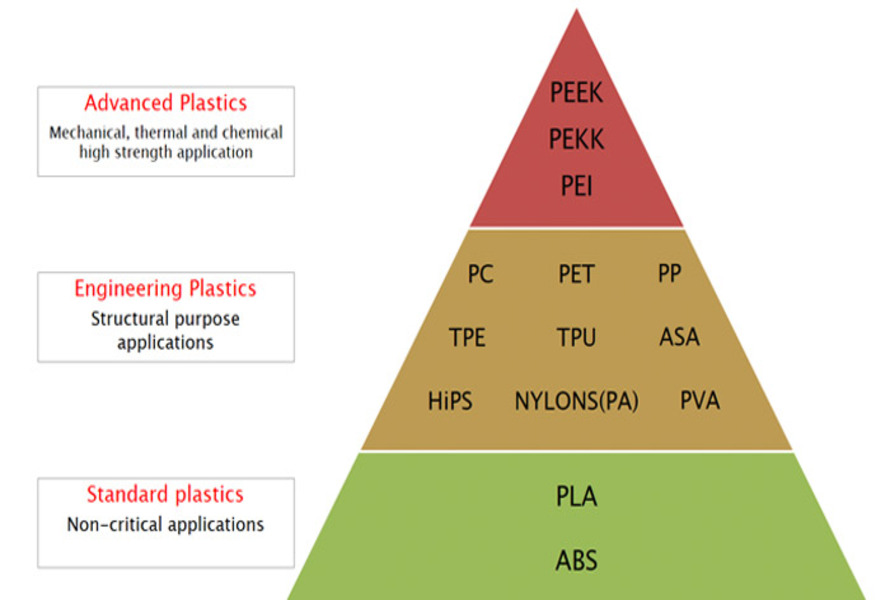

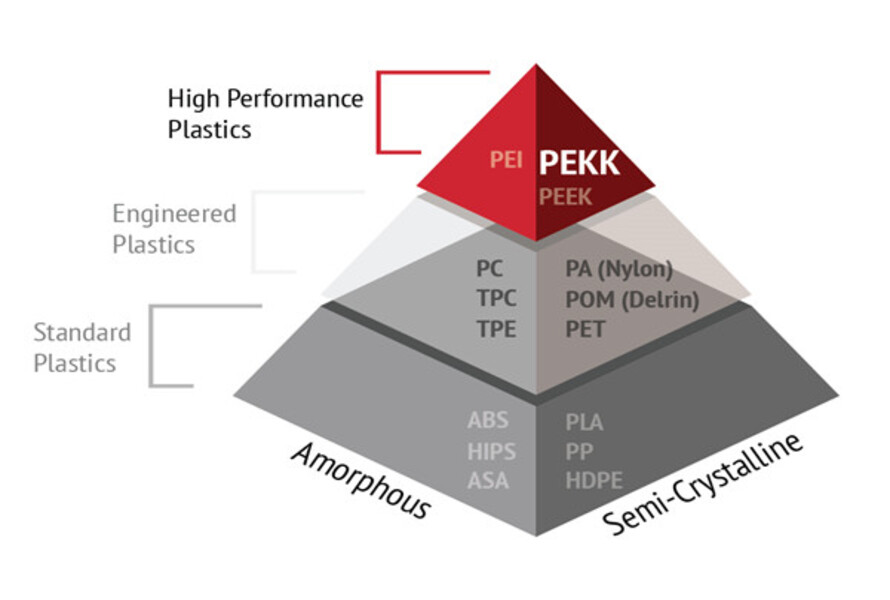

Nhựa PEEK được biết đến là một trong những vật liệu nhựa cao cấp nhất trên thế giới và được sử dụng để thay thế hoàn toàn kim loại. Thêm vào đó, nhựa PEEK cũng là một loại nhựa công trình đặc biệt, chúng sở hữu khả năng chịu nhiệt cao cùng Modun đàn hồi là 3.6 Gpa cũng như cường độ kéo giãn là 170 MPa.

Đặc biệt, nhựa PEEK cũng sẽ thể hiện một cách chi tiết nhất hai nhiệt độ chuyển hóa thủy tinh lần lượt là 140 độ C và 275 độ C. Hơn thế nữa, tính cơ học cùng khả năng kháng hóa chất cũng là điểm sáng giúp nhựa PEEK trở nên phổ biến hơn.

Những chất phụ gia phổ biến trong sản xuất nhựa như: PTFE, Graphite, Ceramic, Carbon hay thủy tinh cũng sẽ được thêm vào quá trình gia công nhựa PEEK để cải thiện nhiệt độ hoạt động. Nhựa PEEK được giới chuyên gia đánh giá rất thân thiện với môi trường hữu cơ và không ảnh hưởng đến sự phát triển của thiên nhiên.

2. Thông Số Kỹ thuật đặc trưng của nhựa PEEK

| Thông số kỹ thuật | Nhựa PEEK - Poly Ether Ketone |

| Trọng lượng riêng (Đơn vị tính: g/cm3): | 1.3 |

| Độ thấm nước tính trong 24 tiếng ở nhiệt độ 23 độ C: | Khoảng 0.14 |

| Độ bền kéo Mpa: | Ước tính 87 |

| Độ giãn nở (Đơn vị tính: %): | 80% |

| Độ bền uốn Mpa: | Giao động từ 142 |

| Độ bền khi xảy ra va đập (Đơn vị tính: Lzod j/m): | Lên đến 3700 |

| Độ cứng tính theo hệ Rockwell: | 88 |

| Nhiệt độ chịu đựng trong thời gian dài: | M98 |

| Nhiệt độ chịu đựng trong thời gian ngắn: | Khoảng 260 độ C |

| Điểm nóng chảy: | Đạt mức 300 độ C |

| Nhiệt độ thấp nhất: | Âm 40 Độ C |

| Điện trở suất (Đơn vị tính: Ω・cm): | Tiêu chuẩn 1 x E16 |

Trong phần tiếp theo, chúng tôi sẽ gửi đến các bạn ưu điểm nổi bật giúp nhựa PEEK chiếm trọn niềm tin của thị trường cũng như được tận dụng triệt để tại rất nhiều nhà máy quy mô lớn.

3. Ưu điểm của nhựa PEEK

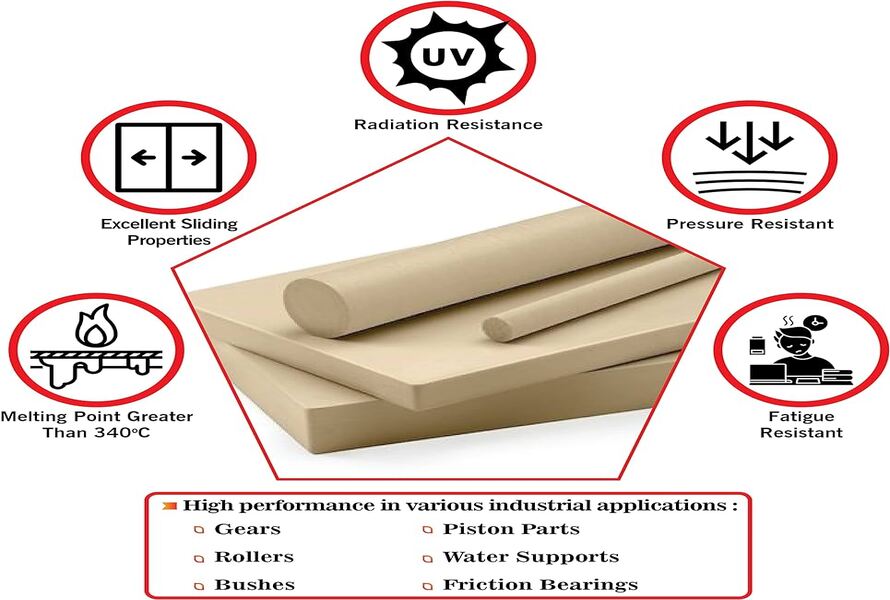

Nhựa PEEK sở hữu đầy đủ những ưu điểm ấn tượng từ khả năng chịu nhiệt, khả năng kháng lực cùng những đặc tính vật lý và hóa học phù hợp trong từng lĩnh vực sản xuất cụ thể.

Thật không quá khi nói rằng, chất lượng của nhựa PEEK là điều không thể tranh luận bởi vì chúng đã được kiểm định khắt khe để ứng dụng trong lĩnh vực hàng không vũ trụ. Điều này cho thấy mọi tính chất hóa học cũng như vật lý phải đạt mức hoàn hảo. Tham khảo ngay 6 điểm mạnh của nhựa PEEK.

3.1 Khả năng kháng các tạp chất và hóa chất

Các chuyên gia đầu ngành đã nhận định rằng, tính chống ăn mòn của nhựa PEEK được xem như gần bằng với thép Niken - một trong những vật liệu bền bỉ nổi tiếng nhất trong ngành xây dựng.

Đặc biệt, Axit Sunfuric loại mạnh là hợp chất hóa học duy nhất có thể phá tan cấu trúc của nhựa PEEK, các loại chất hóa học thông thường hay các dung môi hữu cơ vẫn không đủ khả năng làm điều này. Tính chất này vẫn phát huy rất tốt kể cả trong điều kiện nhiệt độ cao.

Đó chính là lý do vì sao nhựa PEEK trở thành sự lựa chọn phù hợp cho các thiết bị y tế thường xuyên tiếp xúc với hóa chất mà vẫn đảm bảo an toàn cho sức khỏe con người.

3.2 Khả năng chịu nhiệt hoàn hảo

260 độ C chính là mức nhiệt độ trung bình mà nhựa PEEK có thể chịu đựng được trong xuyên suốt quá trình gia công. Đây là mức nhiệt độ cao hơn rất nhiều so với các loại nhựa thông thường chỉ khoảng 150 độ C.

Không những thế, nhựa PEEK đạt mức nhiệt nóng chảy lên đến 334 độ C và nhà mày cần sử dụng mức nhiệt độ gần 400 độ C để đúc thành công nhựa PEEK. Điểm mạnh nhất của nhựa PEEK chính là tính chất vật lý rất khó thay đổi trong môi trường nhiệt độ cao.

Bên cạnh đó, loại vật liệu này có khả năng kháng hơi nước cũng như nước nóng và chỉ được khử trùng bằng hơi nước áp suất cao trong nồi hấp công nghiệp. Đặc điểm này cũng giúp nhựa PEEK rất khó bị phân hủy. Chính vì vậy, vật liệu được ứng dụng trong lĩnh vực hàng không và vũ trụ.

3.3 Vật liệu an toàn cho sức khỏe người tiêu dùng

Luật Vệ Sinh Thực Phẩm Nhật Bản và FDA Hoa Kỳ đã công nhận tiêu chuẩn an toàn của nhựa PEEK đối với sức khỏe con người. Đó chính là lý do vì sao vật liệu này được sử dụng phổ biến trong ngành thực phẩm và dược phẩm.

Nhựa PEEK cũng là vật liệu phù hợp trong các lĩnh vực yêu cầu nghiêm ngặt về hệ số ma sát cũng như tính chịu ăn mòn. Bởi vì thành phần bên trong nhựa PEEK có chứa hàm lượng than chì và sợi carbon.

3.4 Kháng bức xạ

Nhựa PEEK có khả năng chịu bức xạ vượt qua cả hợp chất Polystyrene, đây là vật liệu nhựa công nghiệp có tính chịu bức xạ tốt nhất. Đặc biệt, nhựa PEEK có thể chịu được mức bức xạ lên đến 1100 Mrad.

Ngoài ra, nhựa PEEK là loại nhựa duy nhất có khả năng chống cháy nổ cao mà không cần thêm bất kì nguyên liệu hay chất gì trong quá trình sản xuất bởi vì nhựa PEEK là hợp chất cao phân tử rất ổn định. Mức chống cháy tiêu chuẩn của nguyên liệu đạt từ UL 94V - 0 đến HB.