■ Ultra-High polyethylene (UHMWPE) polymer material uses hermoplastic technique, molecular density can reach 3.0-9.2 million molecules. This density has many capabilities such as high wear resistance, bearing capacity, corrosion resistance, low temperature resistance, selflubricating, impact absorption...

Feature:

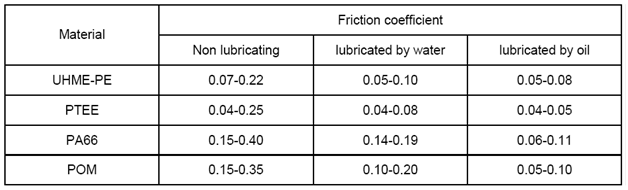

■ Low friction coefficient, high abrasion resistance

■ Excellent chemical stability, corrosion resistance.

■ It is Hygienical, smellless, non-toxic and complies with FDA and USDA standards.

■ Good natural self-cleaning, soundproofing material.

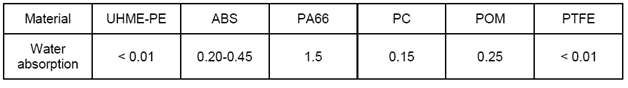

■ Low water absorption, no change in size when environmental humidity changes.

■ Wide temperature resistance range, (-150 ℃ - 85 ℃)

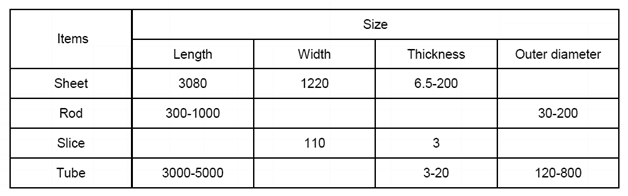

UHMWPE has four product lines:

1. Used in food: white color, conforms to FDA / USDA and 3-A standards in milk production.

2. Premium level: black or grey: molded with the addition of special inorganic and antistatic components with improved properties, well suited for dusty applications where the components Parts need to be lubricated.

3. Anti-static coating: black in color, the materials are free of potentially electrified components, suitable for manufacturing components that easily accumulate static.

4. Oil coated: green, conforms to FDA/USDA standards, applicable to food and pharmaceutical industries. Contains oil additives used to contact lubricating surfaces reducing friction on rotating shafts in dust-free environments.

Specifications table:

Note:

1. Provide cutting services.

2. Color can be customized.

Properties of UHMWPE

■ Has excellent properties

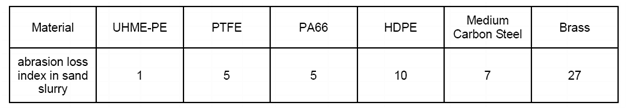

a. abrasion resistance

UHMWPE is the material with the best performance among wear-resistant plastic products, and with higher molecular weight, better performance against wear and good resistance.

UHMWPE is the material with the best performance among wear-resistant plastic products, and with higher molecular weight, better performance against wear and good resistance.

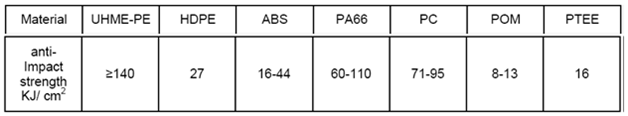

b. Force-resistance

UHMWPE is the material with the best performance among all impact plastic products, with very high impact strength even under -70℃.

c. Self-lubricating

d. Water absorption

Water absorption is extremely low so that the properties of protected materials and machinery will not be affected by wet conditions.