Not only do these blue plastics improve safety, but they also help our customers meet their sustainability targets and improve production capabilities with:

■ Higher processing speeds - our plastics weigh 85% less than metals allowing for higher processing speeds.

■ Longer up-time - our materials are self-lubricating which leads to less wear, reduced external lubrication and longer MTBR.

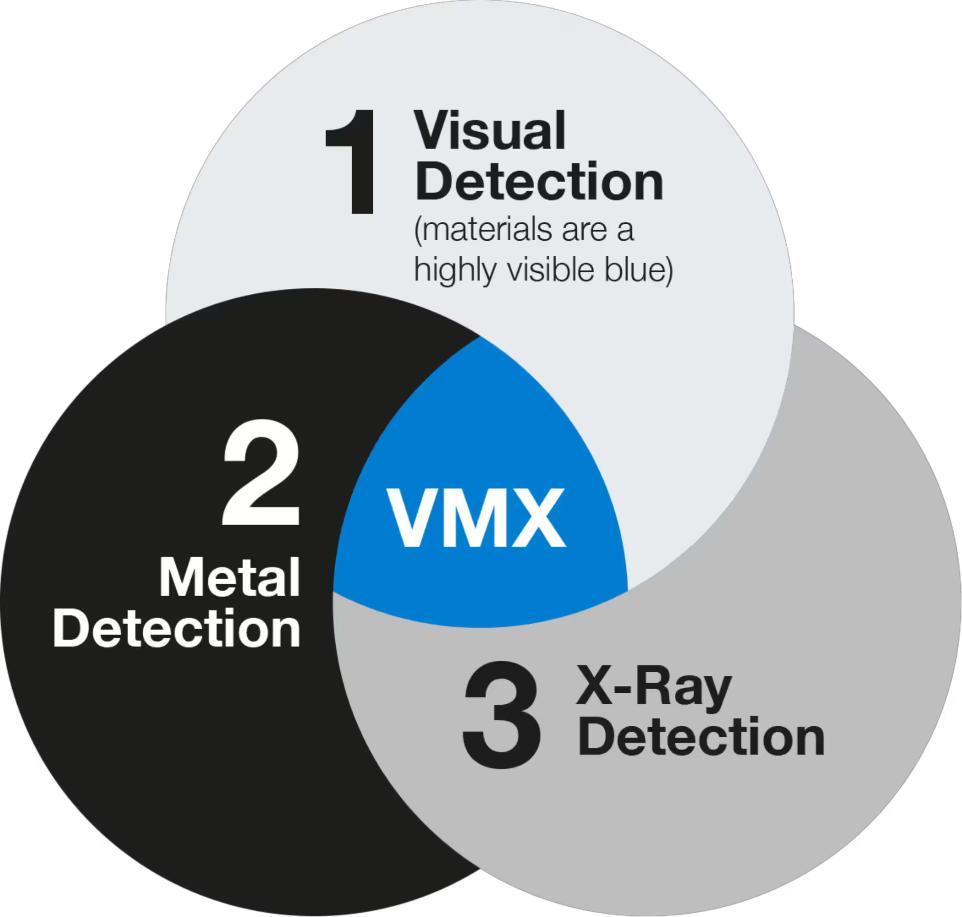

Visual, X-ray, & metal detectable plastics for food processing

VMX is a portfolio of detectable, food safe plastic materials designed to support foreign material control programs in the food and pharamaceutical processing and packaging industries.

Developed in collaboration with food manufacturers and detection technology OEMS, VMX plastics offer the optimal combination of detectability, compliance, and performance.

■ High detectability - These bright blue engineering plastics are detectable in three ways (Visual, Metal, X-ray), with successful detection of particles as small as 2mm.

■ Regulatory compliance - VMX products are food grade plastics with FDA and EU 10/2011 approval for use in food processing. All materials come with migration test documentation.

■ Performance - Great wear resistance to prevent contamination of foodstuffs. The materials are resistant to high temperatures and chemicals used to clean-in-place/sterilize-in-place.

Detectable, food grade plastics

From POM-C to PEEK to nylon to UHMW-PE, explore this selection of blue-colored, x-ray and metal detectable plastics for improved traceability in food and pharma applications.

Acetron® VMX Food Grade POM-C→

Copolymer Polyoxymethylene

A copolymer acetal specifically designed for use in food processing and packaging where it can easily be traced by different detection systems installed to detect physical contamination.

• 3-way detectability: visual, metal, x-ray

• EU 10/2011 and compositional FDA 21

• CFR § 177.2470 compliant

• Good mechanical strength, stiffness, and impact resistance

TIVAR® VMX Food Grade UHMW-PE →

Ultra High Molecular Weight Polyethylene

A metal-detectable, food-grade polyethylene specifically developed to serve as a wear- and abrasion-resistant material with easy traceability in the food processing and packaging industries.

• Three-way detectability: visual, metal, x- ray

• Excellent toughness and impact strength

• Improved wear and abrasion resistance

Ketron® VMX Food Grade PEEK →

Poly-ether-ether-ketone

A metal-detectable PEEK with FDA and EU compliance that offers extreme dimensional stability, high strength, and temperature resistance.

• Three-way detectability: visual, metal, x- ray

• Suitable for food approved parts requiring high stiffness without reinforcements

• Can withstand temperatures higher than 130 °C (266 °F)

• Resistant to steam

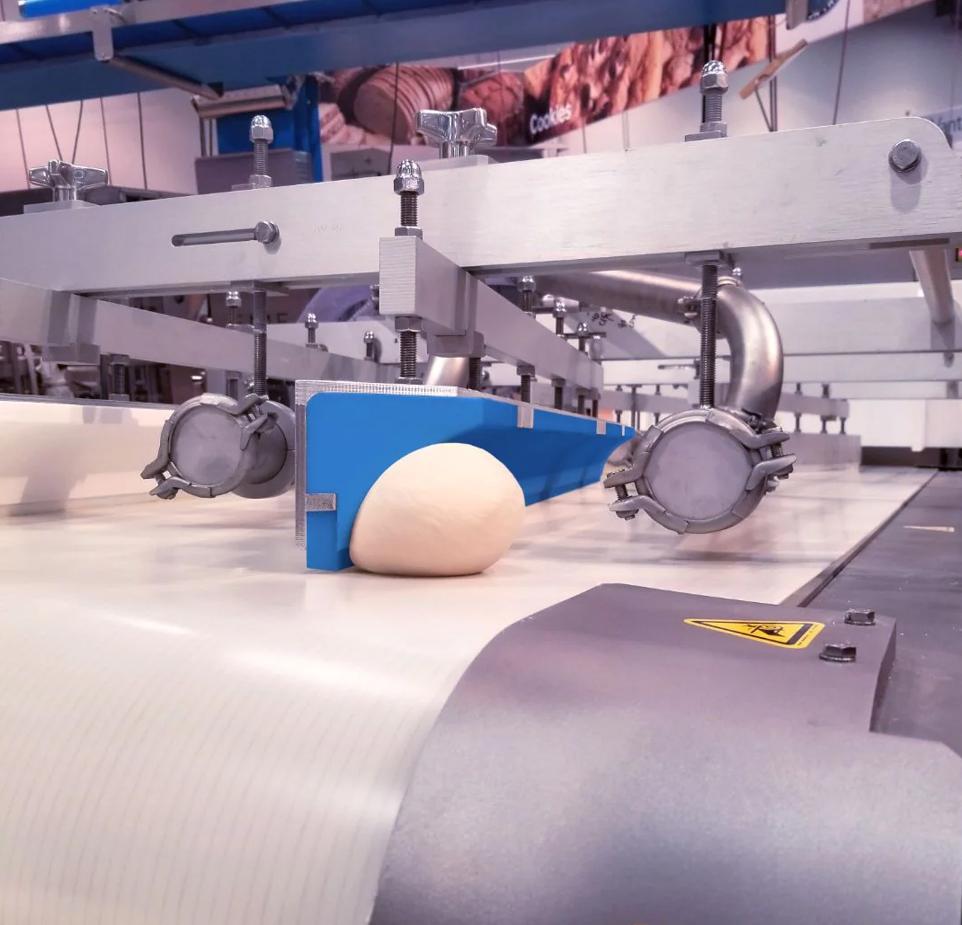

Applications of VMX plastics in the food industry

From POM-C to PEEK, nylon to UHMW-PE, explore our portfolio of green, X-ray detectable and metal-detectable plastics to improve traceability in food and pharmaceutical applications.

Our VMX portfolio spans much more than traditional metal detectable plastics. Even in the most demanding food processing applications, VMX products improve food safety and production efficiency with their superior mechanical properties.

Common food contact applications for VMX products include:

■ Scrapers, grippers, & mixing paddles

■ Cutting blades

■ Funnels

■ Guides

■ Gears & sprockets

■ Extrusion dies

■ Rollers & pulleys

■ Bushings, bearings, & thrust washers

■ Valves & manifolds

■ Many more