1. What is PPE plastic?

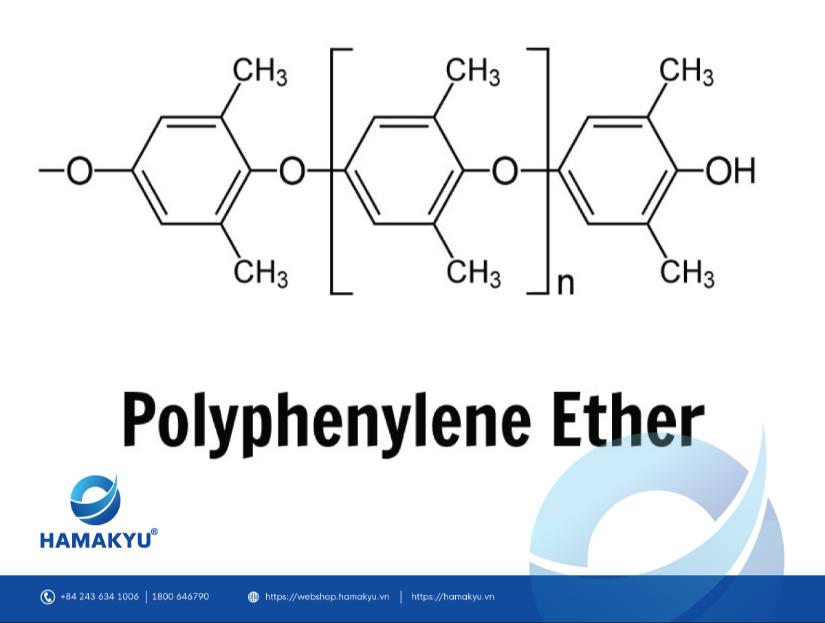

PPE or polyphenylene ether is a high-grade thermoplastic first discovered in 1959 by Allan Hay and brought into commercial exploitation just a year later by General Electric. In some cases, PPE plastic is also known by another name: PPO (Polyphenylene oxide) or the full chemical name Poly(2,6-dimethyl-1,4-phenylene ether).

PPE plastic is commonly known as an engineering plastic polymer with excellent heat resistance, dimensional stability and mechanical properties. Thanks to that, PPE plastic is used for many different purposes, especially in the manufacturing industry.

Overall, PPE plastics are a versatile material that provides a combination of excellent mechanical, thermal, chemical and electrical properties. Let's explore in detail each property and application of PPE plastic with EuroPlas in the next sections of the article.

2. PPE plastic’s properties

Gaining a comprehensive understanding of the properties of PPE plastic allows you to fully exploit the advantages it offers. Firstly, PPE plastic stands out for its exceptional heat resistance, enabling it to survive high-temperature environments without compromising its original mechanical properties.

Secondly, PPE plastic possesses remarkable chemical resistance, withstanding acids, bases, and solvents. In addition, PPE plastic maintains dimensional stability, ensuring the consistency of its shape and size despite different conditions.

Furthermore, PPE plastic is recognized for its fire-resistant properties, ensuring enhanced safety in fire-related situations. Moreover, it serves as an ideal insulating material in the field of electronic industry.

Additionally, its exceptional impact resistance further establishes PPE plastic as a highly durable material capable of withstanding external forces. These outstanding attributes make PPE plastic stand out as a flexible, reliable, and valuable material for numerous industries.

However, PPE plastic also presents certain drawbacks. Firstly, PPE plastic exhibits high viscosity, which can pose challenges during the processing and molding of plastic products using this material.

Finally, the cost of PPE plastic can be considered a disadvantage. In comparison to other plastic materials, PPE carries a higher price, which may serve as a barrier for applications with limited budgets.

3. Applications of PPE plastic

PPE plastic finds its applications in various industries based on its exceptional characteristics and benefits. In the automotive and aerospace sectors, PPE is utilized for air intakes, valve covers, engine components, and under-the-hood parts due to its impressive heat resistance, dimensional stability, size, and resistance to chemicals.

Moreover, in the electrical and electronics fields, PPE plastic is commonly employed in switchgear, circuit breakers, connectors, and socket covers. Its flame retardant and insulating properties also make it suitable for use in household products, dishwasher components, and various kitchen appliances.

The durability and ability to withstand chemicals makes PPE suitable for handling corrosive liquids found in pumps, valves, and filtration systems in industrial equipment. Furthermore, PPE is crucial in manufacturing surgical instruments, IV connectors, and diagnostic equipment that enhance the quality of healthcare services.

PPE plastic has demonstrated its versatility and dependability across numerous industries, showcasing its wide range of applications. In addition, the application of PPE plastic is expanding with new advances, establishing it as the ideal option for businesses and manufacturers.

For advice and detailed information about the product, please contact us!

You can find additional valuable information right here!