What are engineering plastics?

This type of plastic is an upgraded version of primary plastic. In fact, engineering plastics are made from primary plastic combined with some chemicals. Therefore, it will possess the outstanding properties of virgin plastic and the uses of added chemicals.

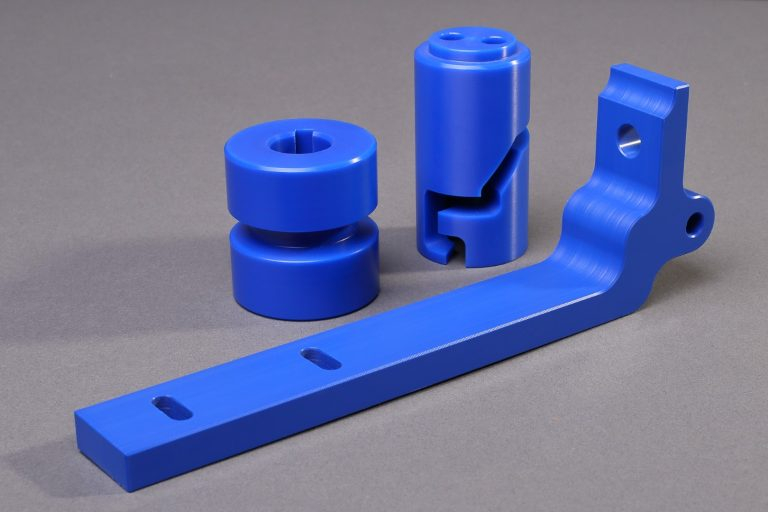

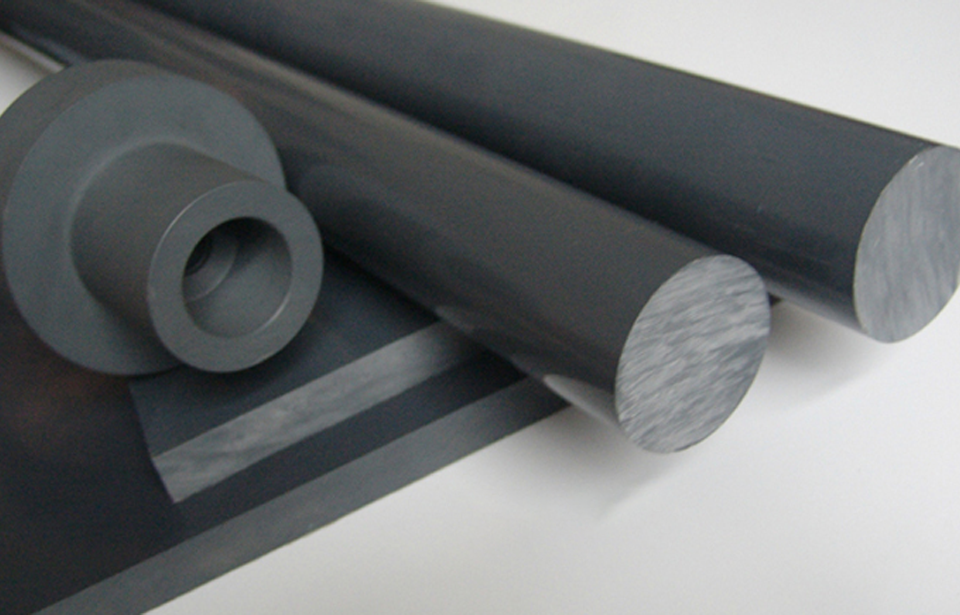

This is a type of plastic specifically used for work related to technical processing. This type of plastic comes in many different shapes so customers can choose depending on their needs. Including rolls, fibers, sheets, trees or bars,...

Common types of engineering plastics

When talking about this type of plastic, you can see the diversity in choices. This plastic also has many types with different compositions. Can say about:

• Bakelite tweezers plastic - a type of plastic widely used in the electronics manufacturing industry thanks to its extremely good insulating ability.

• Alternative material for metal - POM plastic. This type of plastic has good corrosion resistance and high elasticity. In addition, POM plastic also has the ability to lubricate and withstand friction well. The next plus point of POM plastic is its high mechanical strength and durability. The resulting products have very good thermal insulation properties.

• About Teflon plastic: this is a hard plastic with very high heat resistance. In addition, Teflon plastic is also highly appreciated for its ability to limit wear due to friction as well as its non-conductivity. Therefore, mechanical spindles, gears, etc. are often made from this type of material.

There are also other types of engineering plastics such as PVC, HDPE,... Especially PVC plastic is widely used in the construction industry.

Application of engineering plastics

This type of plastic is a material widely used to create industrial products. This type of plastic has many superior features because it is combined from primary plastic with certain chemicals. From there, creating quality products that are useful in everyday life. These include:

• In the electronics industry, this type of plastic is used to create high-tech electronic circuit boards.

• Electrically insulated technical machinery details used in industry.

• Used as lining and partitions that are waterproof as well as insulating.

• This is the main material for making molds in garment factories.

• In addition, this is a type of plastic that is widely used in construction. It is also a component in creating interior products as well as advertising.

Reputable supplier of plastic materials

The increasing number of product uses leads to a significant increase in demand for production materials. That's why Hamakyu decided to expand its products and provide plastic materials for production. We target factories and plastic production facilities on a small to large scale.

With many years of business in the construction industry, Hamakyu has built a reputation for himself. Therefore, customers can feel secure when choosing our materials. Hamakyu is committed to providing quality plastic materials at the best prices.