Plastic properties

MC501CDR2 is an additive compound that provides outstanding performance in low conductivity applications. Nylon's inherent characteristics in MC501CDR2 are high mechanical strength, good wear resistance, noise reduction, chemical resistance, light weight (1/7 of copper), and easy processing. MC501CDR2 has a low surface resistivity of 100 - 102 (Ω/m). Here, it has the ability to conduct electricity, with constant resistivity in all its regions. Therefore, after processing, the electrical conductivity is unchanged. Even if the surface has been worn, the resistivity does not change. In addition, in environments with high humidity, they withstand moisture well and their electrical conductivity remains unchanged. These high-quality technical characteristics make MC501CDR2 quickly become a substitute for metals such as copper, aluminum alloys and wood in many manufacturing fields.

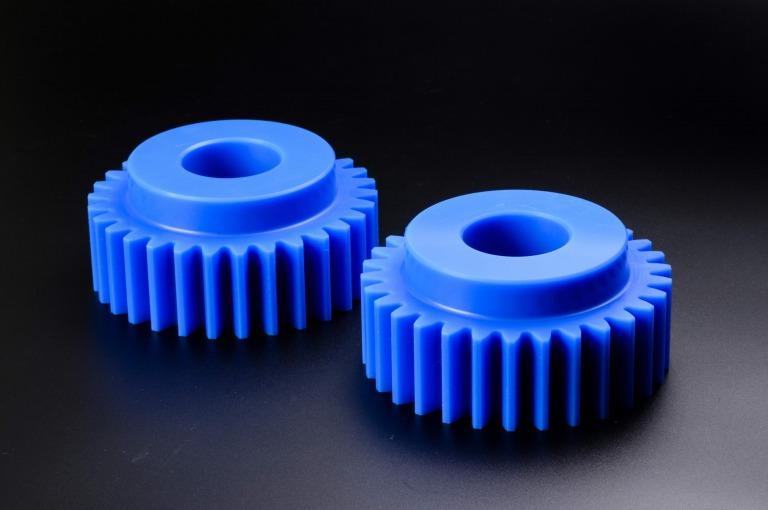

Practical application

While conductive paint or carbon black powder becomes ineffective in conducting electricity, MC501CDR2 is an alternative solution. Among the wheels, guide rollers, support rollers, transmission wheels, and conveyor rollers, bearings, gears, sliding plates, agitator wheels, guides, rings, etc., the MC501CDR2 is used as 1 conductive layer (black) with great durability, long life cycle, cold resistance, low noise and chemical resistance, heat resistance at 120o. These applications are in transportation, storage (magazines, trays, containers), Cleaners (wheels, rollers, guides), printing industry (rolls, plates, guides); paint treatment department...

PVC

MC501CDR2 should not be used as a heat-generating electrical part, contact point, or terminal.

Nylon absorbs moisture or water, in case of use under high humidity or in water, and increases its size (up to 2%). When such use is necessary, consult with the technician and designer accordingly.

· Please consider increasing the size, when you store MC Nylon processed goods for the long term.

· When immersed in boiling water for 2 hours MC501CDR2 can be used legally according to food hygiene regulations.

Size – Volume

MC501CDR2 exists in sheet and tube form.