Cấu tạo

- Kích thước: Dài từ 5000 mm - 10.000 mm, rộng từ 70 mm - 300 mm (Có thể thiết kế theo yêu của khách hàng).

- Khung băng tải: Được làm từ chất liệu inox, thép không gỉ hoặc nhôm định hình.

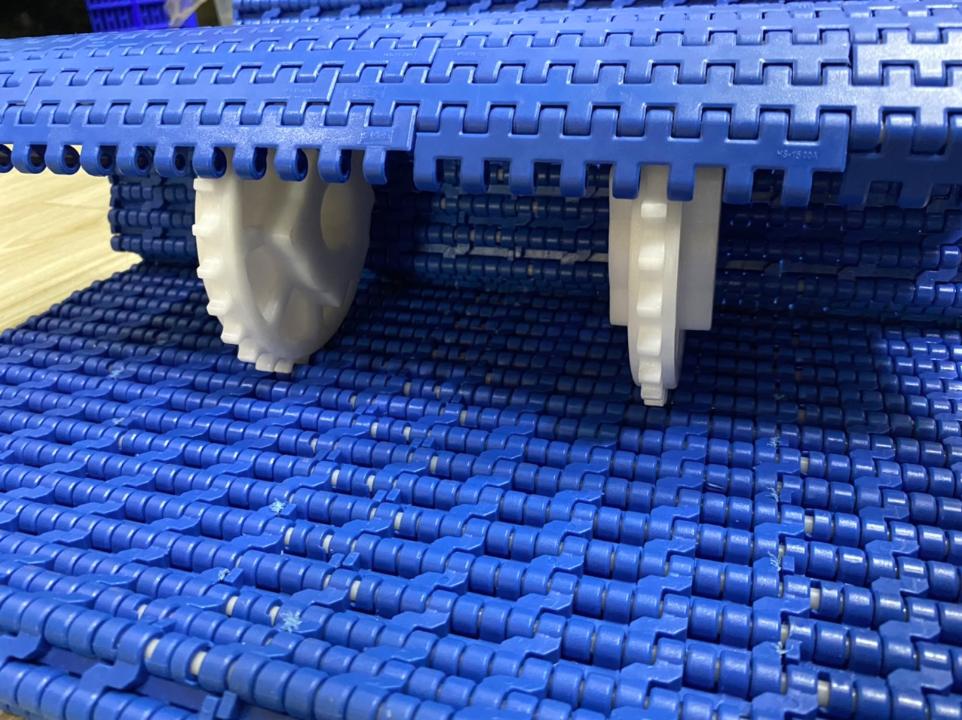

- Dây băng tải xích: Xích băng tải bằng nhựa chất lượng cao và quy cách khác nhau. Tùy thuộc vào ứng dụng mà sử dụng loại dây băng tải xích nhựa phù hợp.

- Động cơ giảm tốc chuyền động: Là loại động cơ giảm tốc có công suất 0.2, 0.4, 0.75, 1.5, 2.2 KW.

- Tủ điện: Gồm các thiết bị biến tần điều khiển tốc độ, Rơ le, khởi động từ, công tắc, timer, công tắc,...

- Hệ thống điện: Tủ điện điều khiển, PLC, hmi, motor, thiết bị phụ cảm biến,...

- Thanh bảo vệ: Có các tay đỡ, thanh đỡ và chắn sản phẩm.

- Các bộ phận khác: Gồm có hệ thống chiếu sáng, đường khí nén,... Nếu các ứng dụng có nhu cầu cần sử dụng đến.

Các tính năng - đặc điểm nổi bật

- Băng tải có khối lượng nhẹ, nhỏ gọn - linh hoạt. Giúp tiết kiệm đáng kể điện năng khi vận hành.

- Có độ bám dính tốt, sẽ không bị trượt, rơi rớt trong quá trình kéo tải.

- Băng tải có cấu tạo - cơ cấu đơn giản. Dễ dàng khi tháo lắp vệ sinh, bảo dưỡng và thay thế.

- Sử dụng các loại xích công nghiệp có khả năng giảm thải tiếng ồn vượt trội hơn các dòng băng tải xích kim loại.

- Có tuổi thọ cao, năng suất hoạt động tốt, chi phí bảo trì thấp. Giúp tiết kiệm nguồn nhân công và một nguồn chi phí đáng kể.

- Dễ dàng điều khiển và vận hành bởi tính năng tự động hóa trong dây chuyền.

- Vận hành tốt trong nhiều địa hình và hình dạng khác nhau. Như đường thẳng, đường cong hay trong địa hình bị hạn chế về diện tích.

- Ứng dụng trong nhiều ngành nghề như bánh kẹo, chai lọ, thùng hộp, hải sản, nông sản,... Có nhiệt độ hoạt động từ -10 - 90°C.

Nguyên lí hoạt động của băng tải xích nhựa

Băng tải xích nhựa có trọng lượng nhẹ hơn 40% so với bề mặt bằng thép. Ngoài ra, còn giảm thải tiếng ồn 70% so với dây chuyền kim loại. Điều này có nghĩa băng tải xích nhựa vận hành rất êm ái và trơn tru nhờ động cơ ổn định. Được đánh giá cao bởi quá trình vận chuyển an toàn, khả năng chịu lực tải tốt, thân thiện với môi trường. Nguyên lí hoạt động của loại băng tải này khá đơn giản - dễ hiểu như sau:

- Khi động cơ hoạt động chuyền tải bằng xích đến tang chủ động. Công suất sẽ được truyền động trực tiếp đến bề mặt của băng tải xích nhựa. Đồng thời, chuyển động tịnh tiến được tạo ra.

- Mặt xích của băng tải xích nhựa sẽ chuyển động. Kéo theo chuyển động của sản phẩm / hàng hóa trên bề mặt băng tải.

- Sự an toàn và tốc độ của chuyển động băng tải được kiểm soát bởi động cơ giảm tốc và biến tần.

Ứng dụng

Ngành sản xuất đồ uống: Chuyên sử dụng để vận chuyển chai và lon đóng gói trong ngành đồ uống, nước giải khát, bia, nước ngọt,...

Ngành thực phẩm: Quy trình chế biến thực phẩm làm sữa chua, sản xuất mỳ, chế biến thịt, cá, tôm,...

Sản phẩm đóng hộp: Các thực phẩm đóng hộp như mì gói, gia vị, sữa đóng hộp, đồ hộp,...

Chế biến, bảo quản rau củ: Vận chuyển các loại rau quả, trái cây, rau xanh, củ quả,...

Sản phẩm y tế: Các sản phẩm y tế ống tiêm, bộ phận máy y tế, sản phẩm chăm sóc sức khỏe,...

Sản phẩm gia dụng và điện tử: Điện thoại di động, máy tính, thiết bị điện tử,...